Cimt – Sensor technology in dental milling machines

Clever automation with IO-Link and RFID

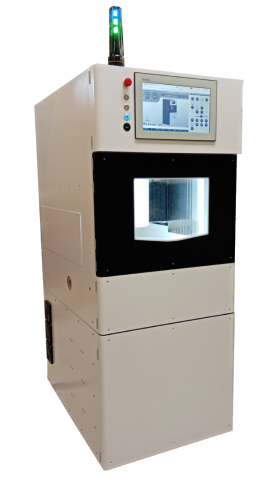

It is the size of a fridge, often works day and night, seven days a week: The 5-axis CNC machine mills components made of special metal alloys for dental prostheses, such as crowns, bridges or implants. Clever automation solutions ensure quick set-up and reliable operation.

The machines are developed and built by CIMT GmbH, a medium-sized company based in Rosdorf near Göttingen. Christian Heine, Developer, says, "We create machining centres for the dental industry. In the first step, we produce this small dental milling machine, mainly for dental technicians and milling laboratories.

However, we would also like to open up other sectors, such as horology. The machine processes semi-finished products, i.e. alloys like gold, titanium, CoCr, zirconium oxide, but also plastics such as PMMA and PEEK that can be machined."

Changing between the different materials is possible in the shortest changeover time and in a few simple steps thanks to the automatic cleaning system of the working area. The integrated tactile measuring calliper ensures direct control of the milling result and accurate re-milling, if necessary. The calliper is also used to calibrate the axes of the machine.

Another special feature of the machine is its compactness combined with its powerful performance. Christian Heine says, "What is special about this machine is its precision, speed and reliability. Another advantage is the little floor space that it requires. Machines from other manufacturers require a lot more floor space to achieve the same cutting performance." The latter is important because dental surgeries or dental laboratories are often in residential buildings.

Heine is particularly excited about the performance. "The machine's speed is currently setting new standards. Considering its size, it machines steel much faster than the machines from our competitors." The production of a crown, for example, in the CNC machine takes about 15 minutes.

In addition to a powerful CNC system from Bosch Rexroth, it is the solid and low-vibration construction of the entire mechanical system that ensures a long service life for the machine and maximum precision meeting industrial standards.

Parts for dental prostheses are milled 5-axis-simultaneously from the "blanks".

IO-Link reduces costs

In order to keep the price of the installation and also the maintenance costs low, Cimt takes a consistent approach. Christian Heine says, "Only components from a small handful of suppliers are installed in the machine. This saves storage and ordering costs."

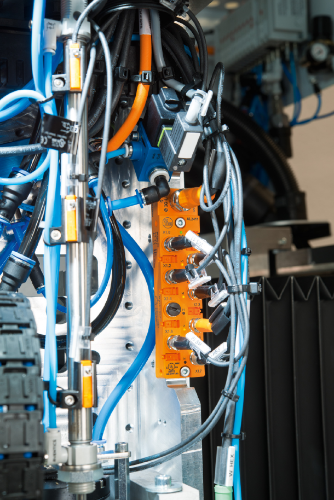

As far as sensors, IO-Link masters, modules and their wiring are concerned, only products from ifm have been used. All sensors are integrated via the IO-Link communication protocol. Christian Heine explains the advantages:

Conventional wiring was always a source of errors. When the machine was set up, many hours were often spent on troubleshooting. Sometimes, components were damaged because the wiring was not done properly. Plus and minus, for example, were mixed up or the cables were not stripped properly.

Picture 1: All sensors and actuators are connected via IO-Link. This reduces errors and time when assembling the machine. Picture 2: Electronic circuit breakers that not only protect the circuit, but that can also switch fans, pumps or lighting via IO-Link. Picture 3: Depending on the workpiece, the user can insert different tools into the cartridge.

Wiring with IO-Link, however, means screwing a connector to an IO-Link master or module. Wiring errors are virtually impossible.

Conventional wiring of all components would have taken 1½ to 2 weeks. Wiring with IO-Link, however, takes less than three days. There were hardly any errors at all."

The signals from the IO-Link sensors are routed to the IO-Link master modules via a standardised M12 connection cable and from there, via Profinet, to the controller. Heine says, "We do not use any inputs and outputs of the CNC controller. We run everything through the IO-Link system. Setting up the machine has become much easier. The process data is immediately available, which requires no programming at all.

This is, for example, how we poll our cylinder sensors, temperature transmitters and flow meters. We also use IO-Link to control, for example, valves or electronic circuit breakers we are using to switch fans, lighting and pumps."

Thanks to IO-Link, faulty sensors can be localised immediately. This helps service engineers because they can connect to the machine via a remote connection if there is a problem. And so they can bring along the right replacement unit for the next service visit. Here another advantage of the system comes into play: When connecting the replacement sensor to the IO-Link module, all parameters will be transferred automatically to the new sensor. This does not only save time, it also further increases process reliability.

Powerful and yet compact machining centre for dental laboratories, horology, precision engineering, etc. equipped with sensors and IO-Link from ifm.

Operating errors will be avoided

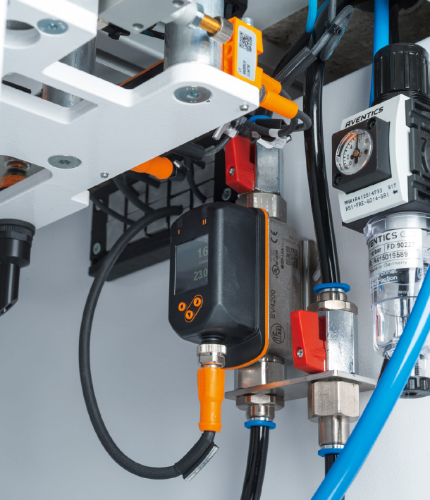

Various sensors monitor the installation. A few examples: cylinder sensors monitor the end positions of the piston rods on the pneumatic cylinders. ifm temperature sensors and flow meters monitor the cooling circuit. Level sensors monitor both the tank for the coolant and the swarf hopper.

The monitoring of the tool cartridge is particularly interesting: depending on the workpiece and the material, different milling tools are used in the individual work steps. The operator first inserts them into the fixtures of the tool cartridge.

Picture 1: ifm offers space-saving IO-Link modules with M8 connectors. Picture 2: The electronic flow meter SV4200 monitors the volumetric flow and the temperature of the cooling circuit. Both process values are transmitted via IO-Link to the controller. Picture 3: The RFID read head checks the tools before the machining process starts. This ensures maximum reliability.

Before starting the machining process, the machine checks whether all required tools are available and at which fixture position the operator has inserted them. For this purpose, an RFID read head mounted on the fixture head moves through all positions in the cartridge. Each tool and each material is coded, which ensures error-free identification and allocation.

The position of the tools is also stored in the controller. Each time the cartridge is opened, this scanning process will be repeated. This offers maximum reliability. Any accidental use of a wrong tool is thus excluded, and the operator saves money by avoiding any scrap that could be produced. The ifm RFID read head also transfers the data via IO-Link to the controller.

Conclusion

An intelligent connection concept like IO-Link in connection with sophisticated sensor technology ensures maximum reliability during installation, set-up and the process itself. This paves the way for cost-effective production.