ifm Vision: from selective distance measurement to industrial imaging

Being a driver of industrial digitalisation, our mission is to make outstanding optical technologies available to companies of all sizes. This also applies to vision sensors, which, as the “eye” of Industry 4.0, play a significant role in the implementation of digital evolution. Our vision: a cutting-edge technology, available to all!

No compromises! Your advantages with our Vision products

The application possibilities for our Vision products are wide-ranging, we offer you:

ifm has been offering vision systems as an easy-to-use solution for industrial image processing since 2003. To this day, all our products stand out for their ease of use. Complex challenges can be set up and solved within minutes.

What else makes our products unique? As the only supplier of vision systems we develop all of the components in-house. This enables us to manufacture TOF (Time-of-Flight) sensors that precisely meet any system-specific requirement.

1D object recognition

Precisely detecting distances, levels and positions

1D position sensors are ideally suited, for example, for non-contact distance measurement or positioning tasks in automation technology. Level measurements, too, can be carried out reliably. In addition, distance values can be directly visualised.

|

I would like to measure lengths reliably over long distances. |

|

I would like to measure the levels of liquids or solids without contact. |

|

I would like to determine the precise position of very small parts. |

|

I would like to distinguish objects based on their colour (reflectivity). |

2D object recognition

Detecting surfaces, shapes, codes and profiles

2D vision sensors make it possible to check whether the contour, surface, geometry or rotational position of an object matches the predefined specification. What is more, they offer solutions for the recognition of codes and texts.

|

I would like to assess surfaces and check for the presence of objects. |

|

I would like to identify objects regardless of shape and location. |

|

|

I would like to match the height profile of an object with the target conditions. |

|

I would like to read barcodes and 2D codes reliably even at high speed. |

3D object recognition

Checking for completeness, detecting moving objects in three dimensions

Image processing in the third dimension - 3D vision systems are used, for example, in conveyor and packaging technology as well as in intralogistics. Another area of application is mobile machines. In addition, they detect objects and persons in the danger zone and thus significantly reduce the risk of collision.

The areas of application of our 3D vision systems can be categorised into automation, robotics and logistics automation, as well as the area of mobile machines.

|

I would like to implement an obstacle detection system for automated guided vehicles (AGVs). |

|

I would like to detect and pick up pallets automatically using an AGV. |

|

I would like to detect the volume of objects. |

|

I would like to capture several objects or distances at the same time. |

|

I would like to grab objects automatically and reliably. |

|

I would like to palletise objects automatically. |

|

I would like to record the fill level of bulk materials. |

|

I would like to check products for completeness in the process. |

Use cases: Our Vision products in the real world

|

Ford: how the 2D profile sensor secures assembly steps in car body construction. |

|

Unchained Robotics: how the 3D sensor contributes to efficient palletising. |

|

Delaval: how the 3D sensor enables a gentle, hygienic milking process. More about its use in the latest generation of milking robots |

|

Technoferrari: how AGVs reliably pick up pallets with the 3D sensor. |

|

Risse & Wilke: how the 3D collision warning set ensures greater reliability. More about the complete set for retrofitting forklift trucks and the like. |

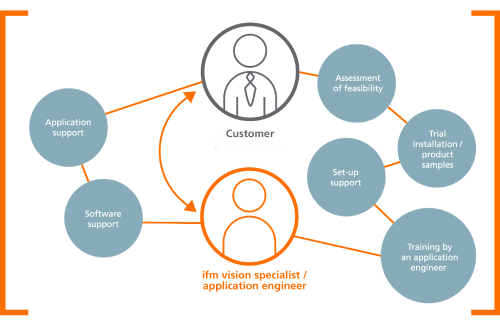

Advice from our experts

ifm will accompany you on your way. Depending on your requirements, the ifm Vision specialist will support you right from the beginning – from application consulting, the development of individual software and hardware solutions and their corresponding implementation to advanced services. Your personal ifm Vision specialist will provide you with the entire ifm know-how to implement and optimise your automation solution.

Together we will make your project successful.