Sustainability thanks to high availability

Condition-based maintenance in the production of pencils

Reliable plant operation

Simple evaluation of

the machine status

Cost savings with

condition-based

maintenance

Results

- Permanent monitoring of important components in the machine

- moneo edgeConnect translates sensor data into easy-to-read information

- Plant downtimes are reliably avoided

- Condition-based maintenance increases the availability and reduces maintenance costs

The challenge

In the mass production of penls, machine faults can quickly lead to high costs. This not only applies to unplanned machine standstills but also to any scrap that may occur. The material scrap of wood should be reduced to a minimum, especially when aiming for a production that ensures maximum sustainability.

The typical machine downtime due to troubleshooting, cleaning and machine restart is over two hours and should be avoided for efficiency and cost reasons. Permanent monitoring of the production machines for faults is here recommended as a remedy. In the past, only a few LEDs had been installed to indicate faults. Hence, extensive monitoring and diagnosis of the machine’s condition had not been possible.

The solution – why ifm?

In order to implement condition monitoring, essential components in the production machines, such as compressors, fans and extruders, have been equipped with vibration and temperature sensors. The values recorded in this way provide an insight into the machine’s condition at any time.

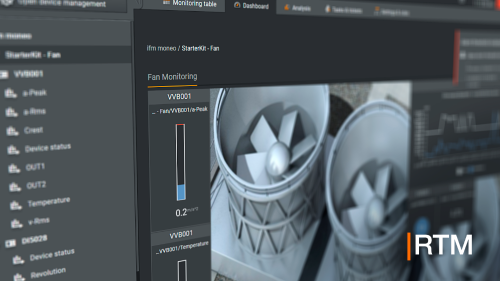

An edgeConnect evaluation unit from ifm is used to connect the sensors and transmit the measured values to the moneo RTM software. This module of ifm’s digitisation platform enables the evaluation, monitoring and visualisation of the recorded data.

With the machine condition trend being recorded, the software can detect imminent faults at an early stage. The diagnostic data provide exact information about the machine status at any time, so that possible faults can often be detected in time and thus avoided. This allows condition-based maintenance to be implemented, leading to an increased overall availability of a machine.

Should a fault nevertheless occur during operation, moneo RTM can immediately notify the responsible specialists by e-mail, who can then quickly take care of the troubleshooting. These machine monitoring functions with moneo RTM increase the plant availability while also reducing the costs. The planning reliability achieved with the detection of diagnostic data have convinced customers instantly of the solution.