Iveco – Diagnostics in the body shop

Sensors allow condition-based maintenance

In the body shop the body is assembled from pressed steel parts with the help of welding robots. Each body must pass along a 100 m production line. A critical spot because a standstill here would stop the whole production. Therefore IVECO have installed a comprehensive diagnostic system together with the ifm automation specialist allowing condition-based maintenance thus effectively preventing unintended production losses.

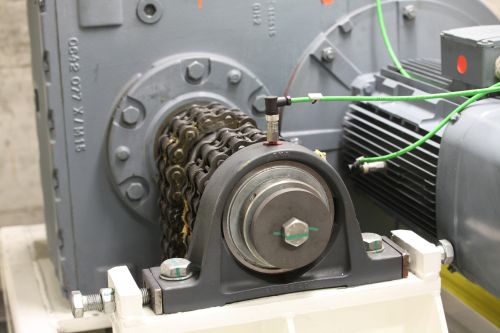

An initial analysis was carried out to determine which parts were most susceptible to mechanical wear and failure. Conveyors or lifting platforms: or more precisely on their bearings is where the most intensive mechanical stress arises. Damage at that spot of the plant would entail considerable production stop.

To ensure maximum uptime of the system imminent wear of the machine components must be detected at an early stage. Fabio Piccinelli, WCM Plant Support IVECO SPA: "We are always looking for new technologies for continuous improvement to increase efficiency and productivity. As far as maintenance is concerned, we have changed from cycle-based maintenance to condition-based maintenance which meant considerable cost savings.“

Vibration diagnostics

In practical terms this means: ifm vibration sensors were installed on all mechanical system parts. The cylindrical VSA-type sensors are directly screwed to the housing of the respective bearing or gear. The separate VSE evaluation units permanently analyse the vibration characteristics. They detect imminent damage due to unbalance and send an early warning. Guiseppe Sotira, Body Shop Technical Engineering IVECO SPA: "The sensors help the maintenance staff to detect the wear status of each component in real time and to introduce any necessary maintenance work before a real damage occurs.“

Picture 1: Vibration sensors monitor bearing and gear. Wear and tear is detected in time. Picture 2: The cooling of the welding guns is monitored by means of the ifm SBY-type flow meter.

Monitoring of fluids

Condition-based maintenance, however, is much more than just monitoring mechanical components. An example is monitoring of the cooling water in the welding guns. Possible error sources are clogged filters or leakage. ifm SBY-type flow meters for small volumetric flow quantities monitor the flow and PN-type pressure sensors the pressure in the pipes.

The central cooling circuit system is monitored by the SM flow meter. The compressed air system is reliably monitored by an SD sensor. Even tiny leakages are reliably detected.

Electronic flow monitoring in the central cooling circuit.

Bottleneck: Malfunction at this spot would stop complete production.

Robots weld pressed steel parts to a body.

All sensors transmit their measured values digitally via IO-Link. Roberto Militello, Body Shop Maintenance IVECO SPA: "IO-Link transmits the data digitally for reliable process control. The measured value is converted into digital data in the sensor and forwarded. Moreover, we can program the switching points of the sensor for early warnings and alarm directly from the server without having to approach the sensor locally. We can see the sensor in the server and calibrate it. Programming after replacement is no longer required.“

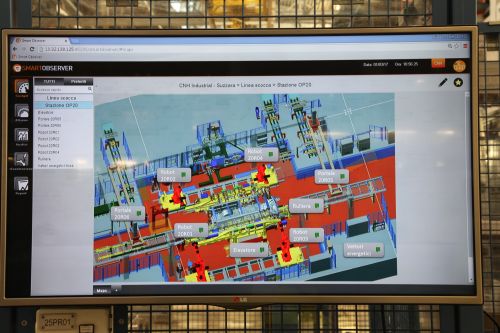

The LINERECORDER AGENT is used as software. It collects the sensor data and stores it in a Microsoft SQL database. The SMARTOBSERVER analyses and displays this data. Once again Guiseppe Sotira: "The ifm software SMARTOBSERVER monitors and administers the measured data from all the sensors. The parameter display shows a clear image of the complete production plant. Each result can be seen clearly. The system sends alerts such, as early warnings or alarms, by email.“ This ensures condition-based maintenance which is perfectly suited for the concept of Industry 4.0.

Picture 1: The SMARTOBSERVER indicates if limits have been exceeded or not reached. Picture 2: The SMARTOBSERVER provides transparency right up to the inside of each individual sensor.

On the left the evaluation units for the vibration sensors, on the right the IO-Link masters which transmit the sensor signals to the higher-level systems.

Retrofitted during operation: ifm electronic IO-Link pressure sensors replace mechanical manometers.

Conclusion

ifm installed the system for IVECO during operation without the production having to be stopped. The new system could be thoroughly tested in parallel operation.

Bottom line: It has proved its worth. Imminent damage is now detected at an early stage and eliminated without any production standstill. To conclude, Guiseppe Sotira puts it in a nutshell: "Thanks to this cooperation with ifm IVECO is ideally prepared for Industry 4.0“.