Revolutionising production planning with artificial intelligence

EVERY PRODUCTION PLANNER KNOWS THE SITUATION:

When one machine is perfectly scheduled, issues inevitably arise in the preceding or subsequent processes. Due to numerous dependencies and variables, planning across multiple work centres has often been an unsolvable task.

With Factory Optimization Excellence (FOX) from ifm, it is now possible to achieve comprehensive and optimised planning.

For the first time, companies can conduct holistic and complete production sequence planning. The AI-powered software continuously and sustainably improves production processes, providing essential support for every manufacturing company. Additionally, the waste of valuable resources is reduced or eliminated.

The smart way to produce!

CONSIDERING ALL WORK CENTRES IN THE PLANT

SOLVING DIFFERENT OPTIMISATION GOALS TOGETHER

INCLUDING ALL PRODUCTION ORDERS AND MATERIALS

PLANNING BUFFER AND WAIT TIMES

ACCOUNTING FOR MACHINE AND MATERIAL DEPENDENCIES

INCORPORATING UPSTREAM AND DOWNSTREAM MANUFACTURING PROCESSES

AN INTENSE RELATIONSHIP WITH A HAPPY ENDING

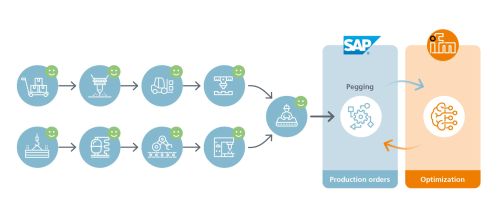

FOX brings together two success concepts to create something groundbreaking: Relationship management meets artificial intelligence. In production planning, all materials, capacities, times, and goals must be identified, and dependencies uncovered. ifm’s supply chain experts have developed a method – including an order pegging logic – that enables the complete analysis of the complex network of dependencies and interconnections. But what happens next? How is a feasible and optimised production sequence created? Algorithms and formulas alone cannot solve this task. That’s why ifm statmath developed the so-called Optimiser. Using artificial intelligence, the neural network achieves the unthinkable: It organizes all "participants" into a smart production sequence that considers all objectives.

Thus, the rendezvous between the relationship manager and AI results in a happy ending for all production planners!

Thanks to order pegging logic and the AI optimiser, production bottlenecks and downtimes are a thing of the past.

FOX works with or without SAP:

HOW FOX WORKS:

- Extracting all information from production orders

- Determining the relationship network using order pegging logic

- Identifying dependencies of all materials, machines, and work centres

- Transferring information to the "Optimiser"

- Calculating the optimised production plan using artificial intelligence

Voilà – the production planner receives a plan that works!

Björn Knabe and Dr Alexander Hoffmann, executives at the ifm group of companies, are the masterminds behind Factory Optimization Excellence. The best of both worlds: The supply chain and SAP expertise of ifm business solutions gmbh, combined with the AI and mathematics know-how of ifm statmath gmbh!

OPTIMAL USE INSTEAD OF WASTE:

Better planning of machine capacities

In (almost) every production there are bottleneck machines that determine the cycle rate of a complete production area and therefore require the special attention of production planning. For this task software tools are available. But practice shows: Even if these tools are used and the planners take the potential bottleneck into account, there are still repeated stagnations and delays in production.

by Gerald Scheffels for ifm