Deep dive FAQ

Discover comprehensive answers to frequently asked questions about the moneo IIoT platform, which is available as a cloud and on-premises solution. Please note that moneo Cloud may not yet be available in your region. Here you can find out about functions, modules, deployment options and more!

General questions

moneo OS

This basic software provides modern user management for flexible assignment of tasks and privileges. Intuitive device management allows for the easy integration of new devices and digital mapping of plant structures. The graphical user interface makes it easy to adjust process values. The operating system moneo OS meets the requirements of Industry 4.0.

No. To use RTM, you need the operating system moneo OS. It is the basis for moneo products such as RTM. You can purchase the function through the moneo IIoT Core basic licence package.

The moneo OS (operating system) forms the software basis for the moneo platform. The functions of the operating system include licence management, user management, device management and data management. With the licence management it is possible to activate moneo licences.

In the flexible user management, users can be created and managed in different groups. The software can thus be made available to specific users with different tasks and authorisations in the company.

The intuitive device management makes it easy to integrate new devices and to map plant structures in order to generate a clear digital image of the plant. Data management allows you to generate information by means of graphic modelling and calculation of process values. It also enables easy integration of calculated values into moneo systems.

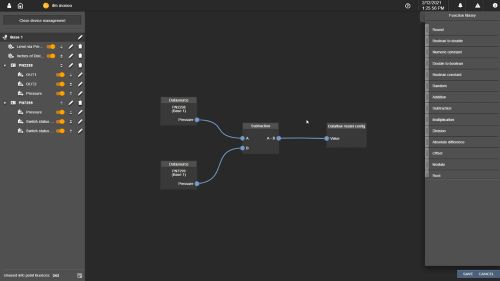

Calculated values enable the conversion of sensor values to process-relevant information with the help of graphical data modelling. Data modelling is based on mathematical and logical operators that can be flexibly selected by the user. The following figure illustrates a possible calculated value.

Please check the technical requirements for the current features.

On the one hand, the user is made aware of warnings and alarms within the moneo software by means of pop-ups. On the other hand, it is possible to set up an email channel so that notifications are sent to the desired email address.

Users can be defined as Admins, Users or Visitors. There are different authorisation levels between the roles.

In the event of alarms and warnings, all user roles or optionally only dedicated persons are notified. This depends on the user’s requirement and can be set individually in moneo.

moneo IIoT Core

BaseBundle - moneo IIoT Core. Optimise your workflows with a single licence key that grants access to all essential functions. With just one licence, you can improve the availability of your machines, monitor process quality or optimise energy consumption. moneo IIoT Core allows you to integrate and manage devices via drag and drop. Configure your sensors at any time. Dashboards provide you with a real-time overview of your data. Evaluate the data with the analysis function and use preventive maintenance to increase the efficiency of your plants. moneo IIoT Core includes all the modules and connectors required to receive the data from the sensors, process it into readable information and analyse it.

The basic functions of moneo IIoT Core are:

For a customised offer, please contact our experts.

Both versions have the same basic functionality. The cloud version uses intelligent data pre-processing to enable efficient storage in the cloud, meaning that only the amount of data relevant to the user will be stored in the cloud. This offers greater flexibility and scalability compared to the on-premises use. The cloud application additionally offers remoteConnect.

remoteConnect enables you to access remote assets. For example, you can remotely maintain systems, manage access and permissions or install updates.

The following operating options are available:

- Windows Installer (system requirements)

- moneo appliance (QHA210; pre-installed on industrial PC with appliance management system for easy IT maintenance and operation)

- moneo vAppliance (QVA200; OVF template for operation in virtualisation environments with appliance management system for easy IT maintenance and operation)

- starter kit (QZ9100)

- moneo cloud

You can flexibly expand your licence package as required. For example, to get even greater value from your data, you can purchase additional infopoint licences (QMI001) or edgeConnect connectors for third-party systems (such as AWS or Azure Cloud).

No. Currently, the moneo IIoT Core can be expanded by the DataScience and Raw Data Recording functionalities for the on-premises environments (starter kit, appliance and vAppliance). We will gradually roll out these expansion options to the cloud version.

moneo configure (free)

The user-friendly configuration software for IO-Link sensors and ifm IO-Link masters. With moneo configure, IO-Link devices and masters can be configured with just a few clicks. Convenient management of your own parameter data sets, including import and export functions, further accelerates the integration of new sensors. Available as a free starter version or as a module for advanced IIoT requirements.

moneo configure is available as a fee-based product for a moneo platform installation with moneo OS. It can be combined with other moneo products such as condition monitoring or AI-based process monitoring. You can purchase the tool in the basic licence package moneo IIoT Core.

moneo configure free is a free stand-alone solution. This version serves as an introduction to simple parameter setting.

Both versions can be extended with the chargeable add-ons for moneo configure. The free stand-alone version does not require a licence key.

No. moneo configure free is a free stand-alone version and can only be extended with configure-specific add-ons. To use configure in combination with your RTM installation, you need the paid module licence.

If V1.13 is installed and the trial period of the configure SA trial version has expired, the moneo configure free version can be selected via a new dialogue within moneo.

moneo configure free is a free stand-alone version of moneo. To use it after the moneo RTM trial version, you must first uninstall moneo completely.

Please make sure that you save the parameter sets of your masters and sensors using the memory function and export them via an .LRP file so that you can import them later.

After uninstalling, please delete the folder at the following path "C:\ProgramData\ifm electronic\moneo".

Now install the latest version of moneo configure free and import your previously saved parameter sets via the .LRP file.

Via an ifm IO-Link master, all IO-Link devices can be configured with the tool according to the IO-Link specification. Support for masters from other manufacturers is in preparation. With configure free, onboarding of third-party masters is already possible.

Please check the technical requirements for the current features.

Currently, the licence is linked to the MAC ID of the computer on which the installation was made. This is a single-user licence.

moneo configure free is a stand-alone version and can only be extended by add-ons for moneo configure.

In order to be able to use the features of moneo configure together with other moneo modules you need the paid version offered as part of the moneo IIoT Core licence package.

The upgrade requires a new installation of moneo.

Direct upgrading is not possible. However, the .lrp files created for IO-Link devices can be imported into moneo configure.

No. Due to Windows restrictions and administrator rights, installation is only possible in C:\Program Files.

moneo RTM

The state-of-the-art condition monitoring system - customised dashboards reveal the status of your plant at a glance and provide immediate damage alerts. External email notifications inform maintenance personnel in good time. Data analyses minimise downtimes and optimise maintenance planning. The RTM Advanced Vibration Analysis add-on enables extended vibration monitoring.

No. To use RTM, you need the operating system moneo OS. It is the basis for moneo products such as RTM. You can purchase the function through the moneo IIoT Core basic licence package.

moneo RTM is characterised by the following functions:

- Monitoring table

- Tabular display of process values and status in customised topology

- Dashboard (graphical visualisation of applications) with process values and status

- Analysis of historical evaluation of process values and status

- Adjustable limits and alarms

- AVA RAW data wizard

- AVA ISO wizard

Yes, an extension is possible through the “Advanced Vibration Analytics” (AVA). The AVA toolbox contains two components: the AVA wizard for defining vibration monitoring of simple machines according to ISO 10816-3 and the AVA raw data recording for manual or rule-based recording of VVB/VSE raw data.

The period of data recording depends on the number of process values, the sampling rate and the size of the database.

The moneo IIoT Core cloud subscription includes the storage of all process values that are booked into the moneo cloud over the period of one year. Data that is older than one year is automatically deleted and no longer available.

Example for on-premises use:

With a number of 500 data points, a sampling rate of 1 value/second and a database size of 64 GB, approx. 8 months of data can be recorded. If necessary, the database size can be adjusted depending on the hardware used. In the case of longer data storage, the database must be adjusted in size.

moneo was developed specifically for condition monitoring of applications in industrial production processes and plants. Machines such as motors, pumps, fans, compressors, compressed air systems and hydraulic units can be monitored. Furthermore, it is possible for larger CIP systems, control cabinets, filters, consumptions and levels to be measured and monitored.

A variety of applications can be monitored and maintained with moneo. Here you can find the application reports on the use cases already implemented with moneo.

Yes. You can add photos and images to customise your dashboard via the web browser. Click on the photo icon and select the desired image.

After adding the photo, you can adjust the image size and position as needed.

The AVA ISO wizard enables customers with little or no experience in machine vibration monitoring to monitor simple but widely used applications such as pumps, fans and engines (drive units) using a standardised vibration parameter according to ISO 10816-3. You can purchase the tool as part of the moneo IIoT Core basic licence package.

Advanced Vibration Analytics raw data recording enables raw data recording for both the VVB and vibration sensors on VSE diagnostic electronics. Raw data recordings can, e.g., serve as a fingerprint or baseline measurement, allow statements about trends or enable detailed damage analysis (see application examples).

There are three ways to trigger raw data recordings.

- Manual recording (e.g. for a baseline measurement or to document unusual machine conditions)

- Rule-based recording, based on a ticket-triggering limit violation

- Rule-based recording, based on a fixed time interval

Similar to a fingerprint, machines, processes and plants have different characteristics depending on how they are used. Existing static monitoring approaches are based on known findings and expert knowledge, rarely representing the real practice accurately. The moneo Industrial AI Assistant uses artificial intelligence to overcome the aforementioned limitations of static threshold monitoring, allowing you to increase the accuracy and validity without requiring expert skills.

The tools differ significantly in terms of their functioning, objectives and requirements. Only their task is the same: to monitor and detect deviating process values.

The moneo SmartLimitWatcher monitors a critical process value (target variable) based on physically dependant process values (support variables). This means that several (sensor) values are required. The trained AI automatically detects anomalies based on automatically defined dynamic warning and alarm thresholds.

Example: dynamic limit value monitoring of the internal temperature (target variable) based on humidity, outside temperature and a time counter (support variables).

The moneo PatternMonitor monitors a stationary (recurring and constant) critical process value without any additional variables. This means that only one (sensor) value is required. Through mathematical calculations the new live data are compared with previous data to detect structural changes (trends, volatility changes, level changes).

Example: monitoring of a single calculated value (pressure difference and flow difference) for leaks within a cooling circuit.

The moneo RTM module is used to monitor process variables based on static thresholds. The moneo Industrial AI Assistant can be used to automatically set dynamic limit thresholds that exactly match the monitored process value.

If possible, the period of historical data used should represent all normal states. Ideally, each normal condition is recorded multiple times. If anomalies or unwanted conditions occur during data recording, such unsuitable data periods can be excluded/deactivated. This allows you to create a data set that consists only of “good” operating states.

Example: If the normal operating process of a pump to be monitored is one week, two to three weeks of historical data should be available during which the pump ran optimally.

The sensitivity is not optimally adjusted to the irregular environmental influences and the monitored process. The training period was not sufficiently representative to cover all standard states.

Example: Someone accidentally bumps against the machine at irregular intervals, which causes vibration and briefly changes the operating process.

The sensitivity controls how soon an anomaly is detected and how sensitive the model is to process changes.

Example: high sensitivity = early warning

Production environments are subject to many unpredictable environmental effects. While setting the highest sensitivity will produce the earliest warnings in the highest number and thus offer the highest level of security, it will also increase the frequency of insignificant alerts.

Example: A door is left open longer than usual, causing a change in temperature. Depending on the application, this does not necessarily lead to issues.

Depending on the tool, a monitoring profile needs to be retrained if the normal ‘good’ condition of the monitored process or environment has changed. See the individual tools for more detailed information.

Example: An oven is installed in the production hall, which has a significant influence on the temperature of the monitored machines nearby. As this affects the process behaviour, a new profile must be trained.

In addition to historical data, you need the moneo IIoT Core and the requested licence for the tools of the moneo Industrial AI Assistant.

The moneo Industrial AI Assistant uses the unsupervised learning approach.

The process value distribution of the monitored variable must be stationary, i.e. the fluctuations in the values remain constant over time. In addition, there must be sufficient data available to describe the process.

Example: In a cooling circuit, the flow difference between the inlet and outlet fluctuates between -1 and 1 bar, but is 0 in the time average.

The moneo PatternMonitor cannot monitor controlled or non-stationary processes.

The tool can detect impending structural changes early.

Example: false-positive alerts due to drift in measuring equipment or batches.

In some processes, faulty behaviour is evidenced by a process variable that always behaves in the same way in relation to the pattern type and direction. To save computing power, time and money, the other setting options can be excluded from the calculation.

Example: The deterioration in model quality only becomes noticeable with a decreasing data curve, which is why the increasing pattern direction can be excluded.

Depending on the target requirements and process characteristics, adjustments should be made. When using the basic presets, a suitable ratio of time resolution and evaluation period will automatically be defined. This means that the user only needs to define a rough time period for the pattern detection, which can be days, weeks or months. By switching to the advanced presets, you can manually configure the time resolution of the data, the pattern type and direction and the evaluation period precisely to the second.

Examples:

- Long process (> 6 months): evaluation period - weeks or months with a rough time resolution (e.g. 1 minute)

- Moderate process (1 - 6 months): evaluation period - hours or days with medium time resolution (e.g. 20 seconds)

- Rapid process (< 1 month): evaluation period - seconds or minutes with fine time resolution (e.g. 1 second)

The configured evaluation period and alarm sensitivity may not be ideal for the underlying process. Environmental factors or external influences can be further causes.

Example: If a person bumps into a sensitively adjusted machine that is monitored, this will be identified as a structural (level) change, which will be perceived as an alarm.

One reason can be that no structural change has occurred. It is also possible that the data and settings (time interval, time resolution, pattern type and direction, evaluation period) have not been chosen well.

If the automatic basic presets do not produce the desired result or if the time resolution and evaluation period need to be optimised, the advanced presets offer you more detailed and precise configuration options.

Example: If the monitored process only has a downward-sloping pattern, it is possible to deactivate the upward pattern in the advanced presets.

The moneo PatternMonitor does not need to be newly trained, as it always uses the most recent data as reference data and compares it with the live data.

Static process monitoring uses general predefined limit thresholds throughout the entire process regardless of what is currently happening. Dynamic threshold setting means that plants can be monitored in a process-focussed manner to detect even slight deviations early. This has the great advantage that no knowledge about the correct alarm thresholds is needed and that process deviations can be detected earlier.

Example: If an error occurs at 50 °C within static limit values (40° and 60°), it cannot be detected. With dynamic limit thresholds, this error couldhave be detected.

The selected data period for the target and support variables should cover all normal states and not contain any known anomalies. All cycles of a process should be recorded several times. Unsuitable data periods can be closed (deactivated) manually in the SmartLimitWatcher.

Example: The normal process of a hot water pump passes through all operational states such as switch-off, idling, partial load and full load within a week. This is why we recommend a data period of two to three weeks.

The target variable is the data source to be monitored, the support variables are used to describe the behaviour of the target variable. The target variable must have a measurable relationship with the support variables. This relationship must be appropriately described by the available data. Avoid using calculated values that are derived from the target variable. An unlimited number of support variables can be used.

Example: If pressure is selected as the target variable, the temperature constitutes an excellent support variable as it usually increases with the pressure. There is a high correlation between the data.

The critical process or machine variable to be monitored should be selected as the target variable. In order to be able to describe the behaviour of the machine, all other physically related (sensor) values must then be selected as support variables. The selected support variables can differ depending on the application.

Example: When monitoring machine health, vibration is a useful target variable as it is a strong indicator of faulty behaviour. Depending on the application, values such as temperature, speed or operating time can be suitable support variables.

Model accuracy refers to how well the behaviour of the target variable can be described by the behaviour of the support variables. This value is calculated from the test data. The data period is divided into training and test data at a ratio of 90% / 10%. This means that the AI only uses 90% of the data for training and checks itself with the remaining 10%. This is used to calculate the model accuracy.

The reason for a suboptimal model result (<80%) may be that important support variables are not available to the model. Another reason may be that the time period does not represent all normal states or that the time resolution is not suitable for the changing rate of the underlying process. The model result can be improved by selecting a different data period, adding more support variables or changing the time resolution (i.e. the accuracy with which a system can determine temporal changes in data).

The reason may be that the trained time period does not include all normal states or that important support variables are not available to the model. It is advisable to train a new model by adjusting the data period, adding further support variables or changing the time resolution.

The training data may have contained too many anomalies that have been similar to the last fault condition. Another reason may be that important support variables are not available to the model describing the current fault condition. Try to train the model with data containing all normal process states and exclude anomalies. For example, you can select a different data period, add additional support variables or change the time resolution.

If the underlying process has changed, the moneo SmartLimitWatcher needs to be retrained.

Example: If a machine is dismantled in factory 1 and reassembled in factory 2, a new profile needs to be created.

The moneo cloud solution employs various security measures and best practices to protect your data. Some of the security features and practices are:

-

- Data isolation: ifm uses logical isolation to segregate each customer’s data from the data of other customers in the cloud. This isolation ensures that your data remains separate and secure.

- User authentication: Users must authenticate themselves with usernames and secure passwords. Multi-factor authentication (MFA) can act as an additional layer of security.

- Compliance with regulations: The moneo cloud solution meets various compliance standards and regulations. Compliance measures help to ensure data security and data protection.

- Regular security updates: Security patches and updates are installed regularly to protect the cloud infrastructure from known vulnerabilities.

- Monitoring and auditing: The moneo cloud operations team uses monitoring and auditing tools to track system activity and detect suspicious or unauthorised behaviour.

- Data backups: Regular data backups are carried out to prevent data loss due to unexpected events or hardware failures.

- Reaction to incidents: There is a well-defined incident response plan in place to respond promptly and effectively to security incidents or breaches.

- Security awareness training: Employees and staff with access to the moneo cloud are trained in security best practices to prevent security incidents related to human error.

By combining these security measures and best practices, the moneo cloud is designed to create a secure environment for your data and IoT applications. However, it is important that customers remain informed about the security functions and actively participate in securing their data and systems.

The moneo cloud is offered as Software as a Service (SaaS). The responsibility for operation and function is split between the cloud service provider and the ifm group. Customers are responsible for managing user accounts and login data.

Customers have exclusive access to the information within their cloud instance. If necessary, ifm Support can be given access privileges.

The moneo cloud is currently operated in the ‘East-US’ and ‘West-Europe’ regions. This fulfils geopolitical requirements regarding where and how data is stored and processed. When initialising the cloud instance, the customer can choose the region of operation. It is currently not possible to subsequently change the cloud region.

The regional provision also ensures effective network connections in terms of latency and speed.

Customers are fully responsible for the creation and administration of their user accounts as well as the user authorisations. It is recommended to only grant privileges that are truly needed by users.

If the customer loses data, there is a risk that it cannot be recovered.

The edgeGateways are authenticated in the cloud via individual login data. When adding a gateway to the cloud, it receives exclusive data for the cloud instance.

The ifm customer is the sole owner of the data or information uploaded to the moneo cloud platform.

The uploaded data and information is stored and managed in the selected regions of the cloud instance.

moneo on-premises (Windows or appliance) and the cloud offering have many common features such as the standardised user interface and similar module functionalities. The main differences between the two deployment options are:

On premises (Windows or appliance):

- Deployment location: With an on-premises installation, moneo will be used within the customer’s own IT infrastructure. It can be installed on a Windows server or on a dedicated appliance. The customer is responsible for the hardware and software infrastructure.

- Self-maintenance: With an on-premises installation, the customer is responsible for the maintenance of the software, including updates. While ifm provides update packages, the customer is responsible for managing the installation.

- Direct connection: Devices and IO-Link masters can be directly connected to the local moneo installation without having to use a moneo edge device.

Cloud (SaaS):

- Infrastructure: The cloud-based moneo solution is offered as Software as a Service (SaaS) and hosted on the Microsoft Azure infrastructure. Customers do not have to worry about the underlying infrastructure; ifm is responsible for the operation, maintenance and updating of the software.

- Data acquisition: The cloud version of moneo always requires a moneo edge device for data acquisition. The data from sensors and devices is transferred to the cloud via this edge device.

Yes, the moneo cloud offering is constantly updated and optimised.

SaaS (Software as a service) is a cloud computing model in which software is delivered over the Internet on a subscription basis. Users access SaaS applications through web browsers or apps. SaaS providers operate and maintain the software and take care of updates, security and scalability.

SaaS has become a popular software delivery model due to its flexibility, cost efficiency and ease of use.

The data stored in the moneo cloud is managed and stored by ifm. ifm is responsible for the storage, security and maintenance of the data in the moneo cloud. Customer data is securely stored and managed by ifm as part of its cloud service offering.

ifm uses the Microsoft Azure data centre infrastructure to ensure the secure storage and availability of the data stored in the moneo cloud. The location of the data centre can be selected according to customer needs, such as data residency requirements, legal requirements and compliance.

Initially, data centre locations in Europe (“Western Europe”) and the USA (“Central US”) are available for data storage.

ifm gives the highest priority to the security of your data in the moneo cloud. You can find detailed information on how we protect your data here.

moneo cloud: 99.5% availability in the last 365 days.

The customer is the owner of the data stored in the moneo cloud and is responsible for it, including compliance with data protection laws and regulations.

You will find all further information here: General conditions for the use of the cloud software

We offer the following options for extracting data from the moneo cloud:

-

- MQTT connector: The connector for external systems via MQTT enables continuous data extraction for each infopoint.

- CSV export: Export selected data in CSV format via the “Analyse” function.

- SAP connector (planned): In the future, we will also be offering our SFI connector for seamless integration with SAP systems. This connector will provide an additional method for transferring data from the moneo cloud to SAP systems.

If you have special data extraction requirements that are not covered by the standard options, please note that the extraction of process values from the cloud may not be a standard function and may require assistance from the service and support team.

The mobile IoT suite is ifm’s self-service platform for creating and managing cloud instances. Users can add the io-key and integrate moneo edge devices with the help of a setup wizard, for which they need their mobile IoT suite login credentials.

A cloud instance is a customer’s personal area in the moneo cloud. The data belongs to the respective customer and is provided securely by ifm. The name, the web address (URL) and the location where the cloud is operated and the data is stored are chosen by the customer. Initial set-up via the mobile IoT suite is a self-service process.

The name of the cloud or instance can be freely selected (maximum number of characters: 40).

The “instance URL” is the web address that is linked to your instance in the moneo cloud. You will later enter this address in your web browser to access your moneo cloud.

“User email” refers to the email address of the person in your organisation who will be the first moneo user. The person will receive an email to log in to moneo once the instance is active. This user can then create further administrators and users.

The region of a data centre refers to the geographical location of the servers and the IT infrastructure of the moneo cloud. Please select the storage location in line with the data protection regulations in your region. The data centre location cannot be changed later.

remoteConnect

moneo remoteConnect enables remote access to sensors, controllers and other IoT network devices, both ifm and non-ifm devices, directly from the moneo Cloud. With a simple set-up, you can create an encrypted end-to-end connection. Integration into the moneo Cloud eliminates complex network configurations and minimises the need for IT specialists. With remoteConnect, reliable remote maintenance can be carried out quickly and easily.

remoteConnect can establish a remote connection to all devices that can be reached via the (TCP) IP protocol. IoT devices, but also ordinary servers or vServers can be addressed.

Yes, as long as the devices are accessible via the protocol, it does not matter which manufacturer the devices are from. Both ifm devices and devices from other manufacturers can be accessed.

remoteConnect establishes an encrypted end-to-end connection between the service technician’s Windows computer and the selected devices. The modern and secure open-source VPN WireGuard is used to make remoteConnect lightweight, fast and secure.

remoteConnect Admins (e.g. mechanical engineers or production managers) can create and use sessions. They can select devices authorised for remote connection. remoteConnect Users (e.g. service technicians) can use the sessions created by the admin and remotely access devices. They can end sessions, but they cannot add devices.

No, remoteConnect only works with the moneo cloud.

remoteConnect cannot be used to share Windows desktops, however, a Windows computer that acts as a server and provides software accessible via IP can be accessed.

remoteConnect is part of the moneo IIoT Core cloud subscription. For a running session, 50 infopoints are used. When the session ends, the infopoints become available again.

The moneo edgeGateway enables communication between sensors and other data sources and the moneo cloud. The device is located in the customer’s network and collects field data. The moneo edgeGateway enables preprocessing and aggregation of data sources before it transfers them to the cloud.

The moneo edgeGateway enables powerful preprocessing and aggregation of data sources. The aggregation options offered by the moneo edgeGateway:

-

- Mean value aggregation: Calculates the mean value of data points in a defined time interval. This is useful to obtain a smoothed representation of the data.

- Total aggregation: Adds the data values in a defined time interval and provides a total. This is useful for tracking cumulative values.

- Min/max aggregation: Records the minimum and maximum data values in a specific time interval. This is useful for monitoring extreme values.

- Aggregation of the last value: Transmits only the last data point, ideal when you need up-to-date information.

You can also use the moneo edgeGateway to perform calculations on the edge device. This means that you can apply mathematical operations to your data before it is transferred to the cloud. This can include the calculation of new values, transformations or user-defined processing to meet your specific application requirements. This function offers flexibility and customisation options when processing your data on the edge device.

Yes, that is possible.

No, that is not possible.

If the connection between the edgeGateway and the cloud is interrupted, no values can be transferred. Accordingly, no alarms will be generated.

However, the edgeGateway has a buffer storage that stores the data temporarily for at least thirty minutes. As soon as the cloud is accessible again, the buffered data is automatically forwarded and made available there.

An infopoint in moneo corresponds to a single measured value provided by a sensor. For example, if a sensor provides three different measured values and you are interested in all three, you need to plan three information points for these readings in moneo.

The number of infopoints depends on how you operate moneo.

Please check the technical requirements for the current features.

No, an infopoint is used for a measured/process value. If your sensor outputs five signals and you want to include all five in moneo, you need five infopoints.

If you need additional infopoints in the on-premises version (local installation) of moneo, you can simply purchase additional infopoint licences with article number QMI001. They are priced per infopoint. This means that you have to add QMI001 multiple times to your shopping basket according to the required number of infopoints.

You can purchase additional infopoints for the cloud version of moneo by purchasing a new IIoT Core cloud bundle. By default, this bundle contains 500 infopoints per minute.

No, infopoints can be flexibly activated and deactivated. This way you can flexibly book data into moneo. An infopoint can be deactivated as required and made available for other sensors or measured values.

You purchase them once for the on-premises version and in subscription rates for the cloud version. You pay a fixed amount every year, meaning that the bought infopoints are permanently available.

No, this is not necessary. As soon as an infopoint is activated in moneo, this measured value is available to all moneo services in the relevant system. No additional infopoints are required to transmit data or measured signals via OPC UA or MQTT.

Yes, that is correct. One infopoint is needed for every piece of information created with moneo. Once this infopoint has been activated, the created value can be used in all moneo services in the respective system.

In the on-premises version, a single infopoint is required to upload a specific measured value to the moneo system constantly once per second.

In contrast, in the cloud version, the number of infopoints required depends on the frequency with which a measured value is uploaded. For example, if a measured value is transmitted to the cloud once a minute, one infopoint will be required for this. If the measured value is transmitted to the cloud once per second, 60 infopoints will be required.

moneo offers functions for secure operation based on the different derivatives (Windows/Linux). As an appliance, moneo provides functions for secure access, use and securing of the solution. As an open system, moneo on Microsoft Windows is dependent on the functions provided by the operating system. Here, the responsibility for security lies with the customer.

The different derivatives offer the possibility to fulfil different security needs, from the appliance with all options to the integrable solution based on Microsoft Windows.

As moneo can only provide functions, the use and the responsibility rests with the customer. When implementing the solution, it is recommended to check the options provided for operation and to configure them according to need. This specifically provides for the use of the user roles and the use of the backup and restore functionalities.

Nein, SFI ist eine universelle Schnittstelle zur Integration von IoT-Daten (IoT = Internet of Things) in SAP ERP Prozesse. Diese kommen häufig, aber nicht ausschließlich aus Produktionsumgebungen. SFI kann dabei auch Daten erfassen, die keine Relevanz für MES-Systeme haben (z.B.: Druckluftverbräuche, Ventilverschleiß oder Ölbeschaffenheit). SFI kann dementsprechend sinnvoll in Koexistenz zu einem MES-Sytem eingesetzt werden.

SFI benötigt nicht zwingend eine Middleware, dennoch ist dies oft der ideale Weg für die Integration von Sensordaten. Die Middleware macht aus Big-Data Smart-Data und bietet zusätzliche Funktionalität, wie die Überwachung von Grenzwerten und Detailanalysen zu Fehlersituationen. Weiterhin wird durch die Middleware eine hohe Skalierbarkeit der Shop-Floor-Umgebung sichergestellt.

SFI ist so designed, dass prinzipiell eine Integration in jeden beliebigen ERP-Prozess möglich ist. Heute liefern wir über unsere RTM-Komponente (RTM = Real Time Maintenance) eine Integration in das Instandhaltungsmodul SAP PM (Plant Maintenance) aus. Dies bedeutet eine automatisierte Anlage von Instandhaltungsmeldungen, -aufträgen und Messbelegen und eine damit eingehende Beschleunigung und Qualitätssicherung. Erste Funktionen zur Integration in SAP Supply-Chain-Prozesse sind verfügbar, bzw. auf der Roadmap für das kommende Release.

Als Beispiel wäre die automatische Nachbestellung bzw. Lagerreservierung von Verbrauchsmaterialien zu nennen. Weiterhin ist SFI in der Lage, Messbelege zu einer Vielzahl von SAP Objekten (u.a. Equipments, Technische Plätze, Produktionswerkzeuge) anzufordern und abzulegen. Damit lässt sich z.B. ein Energiedatenmonitoring unterstützen.

Das ist ohne weiteres möglich.

Durch die Messung der realen Abnutzung von Bauteilen müssen weniger Ersatzteile auf Lager gehalten werden. Durch die Möglichkeit der bedarfsgerechten Instandhaltung sind generell weniger Ersatzteile erforderlich.

Unterstützte ERP Releases

- SAP ERP 6.0 EhP7/EhP8

- SAP S/4HANA On-Premises 2022/2023

Sowohl die gängigen IoT-Plattformen, wie auch SFI selbst bieten Funktionen zur Prüfung valider Daten und Vermeidung von ungewollten Belegen.

Die ausgehenden Verbindungen werden über RFC-Verbindungen realisiert. Eingehende Verbindungen werden per HTTPS und REST-Schnittstelle umgesetzt.

Durch eine frühzeitige, sensorikgestützte Erkennung von möglichen Fehlersituationen, lassen sich Stillstände optimiert in die Fertigungsfeinplanung integrieren. Der tatsächliche Verschleiß der Komponenten gibt die Wartungsintervalle und Instandhaltungsmaßnahmen vor.

In Kombination mit den Hardware- & Softwarewareprodukten aus unserer Unternehmensgruppe sind wir in der Lage, eine ganzheitliche Lösung anzubieten. SFI ist grundsätzlich offen für IoT-Hardware und -Plattformen anderer Anbieter.

Grundsätzlich lassen sich alle Condition Monitoring Systeme (CMS) und IoT-/IIoT-Plattformen, die über eine offene API verfügen, anbinden. Heute sind bereits Anbindungen an ifm moneo, iba HD-Server und die io-key Cloud out of the box verfügbar. Weitere Plattformen befinden sich auf der Roadmap.

Der Weg beginnt bei der Erfassung der Daten über Sensorik und/oder dem Auslesen aus Steuerungen. Diese werden über Edge-Komponenten, die die Vielzahl der möglichen Protokolle beherrschen, an die Middleware übergeben. Dort werden die Daten aggregiert, gespeichert, visualisiert und vorverarbeitet, bevor es dann zu einer Übergabe an das SFI kommt.

Über Retrofitting können auch ältere Anlagen überwacht werden. Mit Anbringen der Sensoren können Daten mittels Plug&Play erfasst werden. Die darauf aufsetzende Integration ins SAP ist mit geringem Aufwand möglich.

SFI setzt auf verschiedenen IoT-Plattformen auf. Welche Sensorik diese verwenden, spielt für das SFI zunächst einmal keine Rolle. Im Hause ifm können wir bei Bedarf alle notwendigen Komponenten aus einer Hand liefern. Die IoT-Plattformen der ifm sind mit allen gängigen Sensoren von anderen Herstellern kompatibel.

Aktuell liegt der Schwerpunkt auf instandhaltungsrelevanten Sensorik- und Steuerungsdaten. Den verschiedenen Use-Cases sind jedoch keine Grenzen gesetzt. Die Lösung kann in den unterschiedlichsten Branchen und Umgebungen eingesetzt werden.

Erste Proof-Of-Concepts (PoCs) sind schon in etwa zwei Projektwochen möglich. Damit können i.d.R. bis zu drei Anwendungsfälle (z.B. Schwingungsanalyse, Ventilüberwachung, Motorstromüberwachung aus der Steuerung) realisiert werden.

Alle SFI-Anwendungen in SAP sind mit Berechtigungsprüfungen versehen, die einen unberechtigten Zugriff verhindern. Darüber hinaus ist die Kommunikation zwischen SFI und der angebundenen IoT-Plattform mit SSL verschlüsselt.

Die SAP Integration eines Sensors aus einer IoT-Plattform ist in weniger als 10 Minuten möglich.

To receive your moneo licences, a licence activation code (LAC) will be sent to you by email after you have successfully purchased your licence regardless of whether you have chosen the on-premises or the cloud solution. This activation code is required to activate the features in your moneo instance.

There are two activation options for the on-premises version:

1. Online activation

Online activation is done by you in moneo. You need to download moneo and enter your LAC under “Online activation” after you have created your moneo account. For online activation, the device on which the moneo instance is running needs to be connected to the Internet.

2. Offline activation

Offline activation takes place via the “my ifm” account. If you do not have an account, you can create one for free.

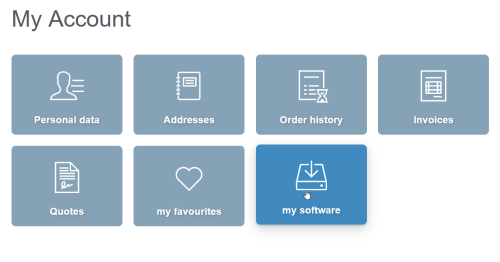

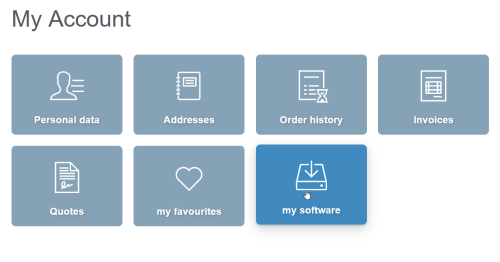

To activate your licence offline, go to “My Account” and select the option “My software” (Fig. 1).

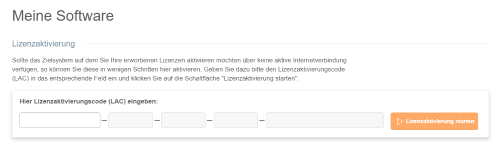

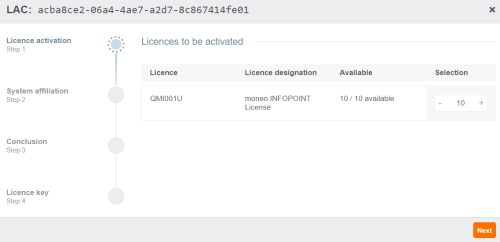

Here you can enter your LAC (fig. 2).

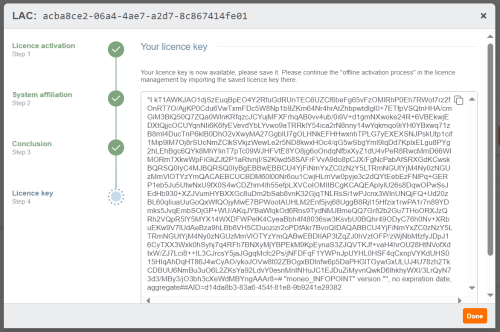

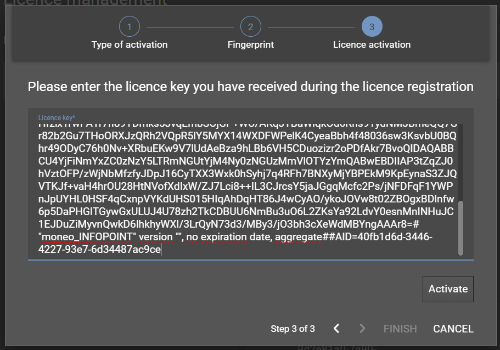

To proceed, you need the digital fingerprint of the system on which you have installed moneo. For this, log in to your moneo instance.

If this is your first login, you will be asked for the type of activation (online vs. offline). Select offline activation.

If you have already activated moneo licences, you can add further licences via the licence management in the system profile (via “+”).

If you have selected offline activation, the fingerprint will be displayed in the next step.

Copy and paste it into the pop-up window on the "”my ifm” page. Follow the steps.

You will receive a code that you can enter in the moneo software under “Offline activation”.

To allocate licences such as infopoints to different systems, please use the offline activation. In the first step of the activation process, you have the option of selecting any number of licences in order to assign them to the system’s fingerprint.

Then follow the activation process described above.

The licence activation codes are be sent to you by email and are available in your “my ifm” account.

If you have lost the licence activation code, please contact our service centre to help you recover it.

In case of need please contact the ifm service centre: 01 461 3200.

Please contact our sales department: 01 461 3200.

In the event that no network connection is available, no data can be collected and/or access to moneo is not possible. Please note that no data can be temporarily stored on the sensors.

To reset your user password, please contact the moneo administrator.

Only users with administrator rights can reset user accounts.

For further information please see the installation instructions.

Please contact the ifm service centre for any questions you may have.