Focus on sustainability: efficient tracking of processes and products

Sustainable tracking with moneo Track & Trace as the key to success

Goal of the project

In today’s production, components and materials often travel a long way before they are processed into an end product. They pass through various processing steps and possibly different locations that must be documented. This is the only way to efficiently track supply and cold chains, downtimes and necessary deliveries.

ifm has developed an innovative solution to ensure maximum transparency and the highest product quality: moneo Track & Trace. Track and Trace enables product tracking, the documentation of individual work steps, the localisation of returnable load carriers, detailed KPI monitoring, rapid troubleshooting, as well as automated posting orders, for example in SAP.

In addition to optical identification systems (code reading), RFID technology can be used in conjunction with the intelligent moneo software solution. This allows the exact position of components or products to be determined and continuously monitored. One example of this is workpiece carriers that go through several steps in production.

Discover the benefits of moneo Track & Trace and take your processes to the next level!

Transparent processes and |

Identification of |

Ensuring |

|

On average, customers achieve: |

||

|

100% transparency of |

up to € 5000 savings in material and |

100% ROI after |

Efficient tracking of processes and products

- Aim of the project

- Transparency and responsibility: sustainable tracking made easy

- Measuring sustainability: this makes it easy to keep a close eye on your processes and products

- Easy data exchange with moneo Track & Trace

- How to optimise your processes and products: a case study with moneo Track & Trace

Transparency and responsibility: sustainable tracking made easy

The aim of sustainable tracking is to create transparency and organise processes efficiently to ensure consistently high product quality. moneo Track & Trace offers you exactly that: it creates transparency and reveals weak points and bottlenecks from which optimisations can be derived. Automatically generated performance indicators provide information such as the number of parts produced per hour, average dwell time, and throughput time.

For example, when monitoring workpiece carriers, the current quantity in the system is known at all times and can be easily monitored. This enables complete traceability. The integrated search function allows you to quickly and easily locate specific workpiece carriers and determine their location and history. In addition, moneo Track & Trace can be seamlessly integrated into existing structures. The wide range of IO-Link identification systems (OCR, codes, RFID) makes it easy to extend existing processes.

Experience how moneo Track & Trace optimises your production processes and ensures maximum transparency.

Value proposition

|

|

|

Measuring sustainability: this makes it easy to keep a close eye on your processes and products

Workpiece carriers are used in many systems to transport objects through different workstations. Identification systems such as RFID are used here to enable data exchange between the individual workstations on the one hand and to uniquely identify the objects on the workpiece carriers on the other. In this example, four pressure sensors installed on the workpiece carrier are being tested. For this purpose, the workpiece carrier is moved through the individual workstations on a conveyor belt.

The RFID transponder (e.g. workpiece carrier number) is also installed on the workpiece carrier and documents the current processing stations. The stations’ identification systems read data from the RFID transponder. Before each station, the information is read from the transponder and processed by moneo Track & Trace. This creates transparency in the system and contributes to the quality assurance of processes and products.

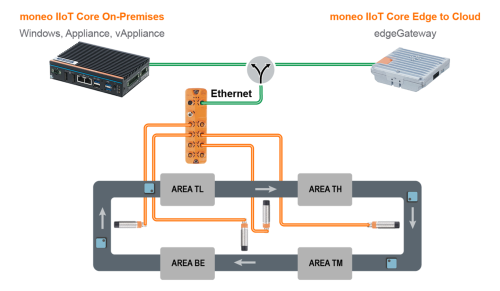

Easy data exchange with moneo Track & Trace

With moneo Track & Trace, the choice is yours: use our solution either in the moneo cloud or on-premises. During the production process, a reader detects important information from the RFID chip which is attached to the workpiece carrier and passes by the reader on the production line. This reader sends the data to the IO-Link master, the IO-Link master transmits the values from the sensors to the software via Ethernet. The moneo software solution counts how many times the workpiece carrier has passed and when maintenance is required.

Each RFID chip contains a unique number that enables precise tracking and monitoring of the current position. The IO-Link master transmits the collected data via moneo either to your ERP system or to the cloud for further analysis.

With an on-premises solution, moneo Track & Trace offers additional advantages: with ifm’s own SFI interface, for example, transfer postings from storage location A to storage location B and eKanban processes can be triggered automatically.

How to optimise your processes and products: a case study with moneo Track & Trace

Four additional RFID reading stations are installed between the workstations to monitor the workpiece carrier. Care must be taken not to interfere with existing stations and to maintain the appropriate operating distance from the data sheet.

The additional workstations are implemented with IO-Link RFID read/write heads with HF (DTI425). These can be easily connected to an IO-Link master with an IoT interface (AL1352) which makes the data available to the central moneo system.

In contrast to existing RFID systems, the workpiece carriers are not stopped at the read/write stations so the data must be read out dynamically. Reading the unique ID (UID = Unique IDentifier) of the transponder is the most reliable option. The assignment of the ID to the actual workpiece carrier number is done within moneo Track & Trace. For this purpose, each tag ID is assigned the corresponding attribute "Carrier ID" (workpiece carrier number).

Air filter system structure

- AL1352 IO-Link master

- 4x RFID reading stations with HF DTI425

moneo software

- moneo Track & Trace

|

|

The following products can be sourced from third-party companies: DE46 |