- moneo: IIoT platform

- Use cases

Consumption monitoring: Organisation of sustainable and energy-saving manufacturing processes

Visualisation and analysis of the consumption of cooling circuits in production using moneo RTM

In production, cooling water is provided, for example, for cooling of lasers. A decreasing cooling capacity, for example caused by an insufficient water supply that is detected too late will increase energy costs and, in the worst case, lead to overheating and, thus, to a plant failure.

This can be remedied by measuring the consumption and calculating the heat output of the cooling circuit.

The initial situation: no measurement of the consumption

Up until now, the customer had no decentralised recording of the consumption. Only the total consumption was recorded, an exact assessment of individual consumers was not possible - and, thus, no specific planning of efficiency-enhancing measures or maintenance was possible.

Goal of the project: increased process reliability

By using more process sensors, detailed energy monitoring of the individual sub-areas was to be made possible in order to include the energy consumption per product in the manufacturing costs. The temperature monitoring system was also supposed to detect when the ideal temperature is exceeded or not reached, so that a reduced cooling capacity or leaks can be quickly detected. As a further aspect, the consumption of the industrial gases in use were to be recorded digitally. The entire information was supposed to form the basis for "green production" and also meet the requirements of the energy audit according to DIN EN 16247-1.

The implementation: consumption monitoring with moneo RTM

At ifm prover gmbh, moneo RTM is centrally installed on a server.

The IO-Link master is connected to the server via an internal VLAN.

The process sensors are connected to the master via IO-Link.

The successes achieved so far: Transparent, detailed recording of all relevant energy consumptions with moneo RTM

With moneo RTM, the customer can keep an eye on all individual consumptions and, thanks to the Calculated Values function, simultaneously combine them into an overall result. This enables the customer to identify deviations from the ideal condition individually for each consumer and thus initiate targeted maintenance or optimisation measures. The investment in moneo was thus also an investment in a more efficient use of resources, resulting in sustainable cost reductions.

Bottom line: These features and services of moneo RTM provide added value in energy and resource monitoring

- Calculated values: Sensor values can be converted to process-relevant information with the help of data modelling

- Cockpit functions: comprehensive and individual visualisation of all sensors in the process

- Detailed information about the individual media consumptions by acquiring sensor values

- Integrated alarm management: Fast reaction to changing process parameters

- Monitoring of heating and cooling circuits

System setup

- IO-Link master

- Fluid monitoring system

Dashboard

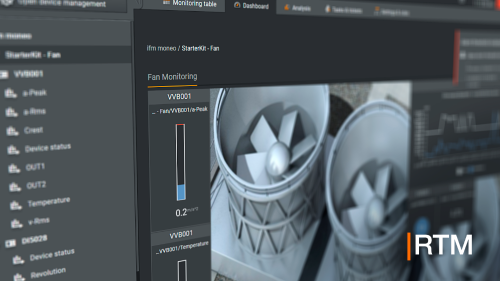

The dashboard provides the user with an overview of the relevant process values for this plant.

- Temperature of the medium in the return line

- Temperature of the medium in the feed line

- Volumetric flow quantity since the last reset (quantity meter)

- Current volumetric flow in the system in litres per minute

- Calculated thermal energy

Analysis

The analysis makes it possible to observe and evaluate the consumption in the history.

Tasks & tickets: start/stop limit values with moneo RTM

Limit values for the sensors are defined in moneo RTM. Alarms are triggered if limit values are exceeded or not reached. Among others, the following values are considered:

- overflow at SM6000 (leakage / hose burst / cap break)

- excess temperature in the feed line at SM6000 (cooling system failure)

- excess temperature in the return line at TA2405 (excess plant temperature)

Calculated values: Calculated values

A decisive process value in a cooling circuit is the thermal energy, from which the current system performance can be determined. Several process values (flow rate, temperature in the feed and return lines) are used for calculation.

- Flow in L/min

- Constant 60 (1h = 60min)

- Calculation L/h = V

- Thermal capacity for water 0.00116 kWh/(lK) = ρ*Cp

- Temperature of the feed line

- Temperature of the return line

- Temperature difference = ΔT

- Thermal output in kW = Q