W. v. d. Heyde – Leak testing of aluminium wheels

IO-Link helps with leak testing of aluminium wheels

If a car wheel loses air, most of us naturally assume a tyre puncture, and rightly so. But only few people are aware that rims can also leak air. The reason is that when making wheels, liquid lightweight metal is poured into a mould. During this process, fine pore cracks or leak paths can occur through which air can later escape. This is why manufacturers of aluminium wheels thoroughly inspect the rims for leaks before putting them on the market.

W. v. d. Heyde, a family-run medium-sized company based in Stade, Germany, has specialised in the production of industrial leak detection machines for the automotive industry. Managing Director Gerald Lüdolph explains: “With a current staff of about 90 employees, we design and manufacture customised solutions for leak testing with test gas against vacuum. Our expertise dates back to the mid-1990s, when we began developing leak detection machines for aluminium wheels. Today, we distribute our products globally and have established ourselves in this field as a world market leader.”

Test procedure

The leak detection machines rely on vacuum technology and gas injection. For leak testing, the wheel rim is sealed on both sides using a rubber plate and a cover. Then, the outside and inside of the rim are evacuated using vacuum pumps. Finally, a test gas is admitted to the sealed exterior of the rim. Helium is typically used for this purpose as it is particularly effective in detecting even fine leaks.

Due to the pressure difference between the exterior and interior of the rim, the helium gas mixture will pass through any potential pores or capillaries into the inner area of the rim. Here, the helium concentration is measured using a highprecision mass spectrometer. As long as it does not exceed a certain threshold, the aluminium wheel is considered tight, otherwise it is rejected.

Before the wheel is approved, the helium test gas mixture is extracted and recovered. “Thanks to this process, we can offer our customers a high level of cost efficiency, as the used test gas is not released into the atmosphere but recycled,” says Jens Westmeier, Team Leader Mechanical Design at von der Heyde.

Image 1: Aluminium wheels are checked for leaks using vacuum technology.

Image 2: Leak tester of the company W. v. d. Heyde.

Image 3: Flow sensors detect compressed air as well as a helium test gas mixture.

Machine redesign

In the past, leak testing and test gas processing occurred in separate parts of the machine. This has changed fundamentally with the redesign.

“The key objective of the redesign was to turn two separate machines into one in order to reduce the footprint and offer our customers a compact solution that incorporates all the necessary functions previously performed by two machines. This saves a lot of space in the customer’s production hall,” says Jens Westmeier.

Automation with IO-Link

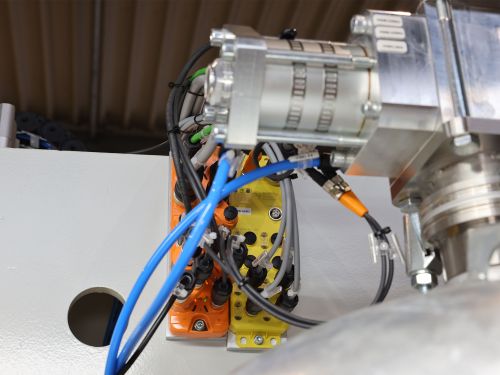

As part of the redesign, the sensor level was completely converted to IO-Link, which offers many benefits. Joost Bochynski, responsible for control technology, explains: “We use a variety of sensors from ifm, including photoelectric, flow and pressure sensors. Thanks to IO-Link, we can optimally analyse these sensors and obtain a lot of previously inaccessible information. One example is the SD flow sensor, of which we use several versions: SD6500 for compressed air, SD6600 for forming gas and SD6800 for helium. The sensors allow us to derive consumption trends, which would not be possible with such precision without IO-Link. Thanks to the extended information from the sensor, we can collect daily, weekly and monthly consumption data in the controller, provide customers with insights into important trends and detect internal leaks in machine lines. Our customers ultimately benefit from cost savings. Efficiency and quality have greatly improved through the use of IO-Link sensors when compared to analogue signals. We can now determine much more accurately whether a sensor, e.g. the pressure sensor, has a problem or functions reliably. Our diagnostic capabilities were not as extensive before, which meant that automation was much more difficult. Thanks to the diagnostic function via IO-Link, we can stop the process in time and avoid expensive subsequent faults.”

Connecting analogue sensors via IO-Link

In addition, conventional analogue sensors with 4...20 mA output can be seamlessly integrated into the IO-Link infrastructure using the DP2200 converter plug. One example are the vacuum pumps, which feature high-precision absolute pressure transmitters (PT0505) with analogue current output. The converter plug integrates these sensors digitally into the IO-Link infrastructure and connects them to the controller.

Image 1: All sensors and actuators communicate with the machine controller via IO-Link master modules.

Image 2: Even safety-related functions can be implemented using special IO-Link masters.

Safety over IO-Link

Even safety-related signals can be transmitted via IO-Link. W. v. d. Heyde uses the AL200S PROFIsafe IO-Link module from ifm.

Thorben Reyelt, Team Leader Electrical Engineering: “We have integrated the AL200S IO-Link module into the machine so that we can safely stop the movement of the actuators. This means that our machine remains in a safe state and stops when the door is open. Operator safety is ensured as no movement can take place in the machine in this state. This is especially important when performing maintenance work or checking processes within the system.”

The PROFIsafe IO-Link module has safety-related digital inputs and outputs that can be used, for example, to connect safe mechanical contacts, actuators or OSSD sensors. It is controlled via the PROFIsafe telegram, which is tunnelled via IO-Link. The AL200S module features eight digital inputs and four digital outputs, the latter with a maximum rating of two amperes.

Status indication

The status of the test system is clearly indicated by optical signals. The test area is equipped with coloured LEDs, which light white during system set-up. Once the rim test is completed, the LED colour visibly changes to green or red depending on the test result.

In addition, the machine and test status is displayed in colour on the machine roof using a 3-segment LED light tower of type DV2310. The light tower can also be conveniently controlled via IO-Link.

Moreover, W. v. d. Heyde took advantage of a special feature of the light tower: If the flow sensors detect a leak in the pipes of the system, a leakage detector is used to find the leak, which the user manually guides along the pipes. The measurement signal from the leakage detector controls the audibility of the buzzer integrated in the light tower in the range from 0 to 100 per cent via IO-Link. So, the closer the detector gets to the leak, the louder the buzzer signal becomes. This acoustic feedback enables the user to easily and quickly pinpoint leaks on the machine, even in noisy production environments.

The IO-Link-based LED light tower is clearly visible from a distance and features an integrated buzzer.

Conclusion

By switching to IO-Link-based technology, the company W. v. d. Heyde was able to significantly improve its leak testing process for aluminium wheels. Through the integration of IO-Link into the sensor level, not only are conventional sensors used more efficiently, but safety-related signals are also transmitted safely. The possibility to signal both the machine status and the test status visually and acoustically improves ease of use for operators and helps to identify problems quickly. Overall, the IO-Link technology used at W. v. d. Heyde enables more precise, more efficient and safer leak testing of aluminium wheels, which ultimately leads to higher quality and cost efficiency in production.