- moneo: IIoT platform

- Products

- moneo DataScience Toolbox

moneo DataScience Toolbox

An intelligent tool kit that reliably monitors critical process values and provides you with a wide range of added value features and important insights into industrial processes.

Ever-increasing product and process requirements place high demands on the entire production process. It is therefore important to use sensor data, values and information from industrial production to detect and eliminate product and process deviations – so-called anomalies – as quickly as possible and automatically.

moneo DataScience Toolbox is a collection of software tools that enable you to easily monitor and optimise manufacturing processes on the basis of artificial intelligence, without the need for data science expertise or programming skills.

The AI algorithm uses the data recorded by sensors. The data are used by advanced technologies, such as machine learning, to ensure the best possible predictions and condition monitoring processes.

Intelligent algorithms promptly report detected anomalies and patterns, understand complex correlations and make reliable predictions.

To put it in a nutshell: moneo DataScience Toolbox simplifies monitoring and optimising your production processes. It also supports the qualitative and sustainable improvement of your company’s production process. Moreover, it helps you to increase efficiency and to significantly reduce error incidence.

What moneo DataScience Toolbox can do

Easily build

Autom

Reduce

moneo DataScience Toolbox

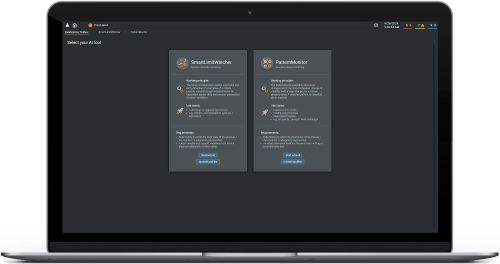

moneo SmartLimitWatcher:

Intelligent monitoring and optimisation of your production processes.

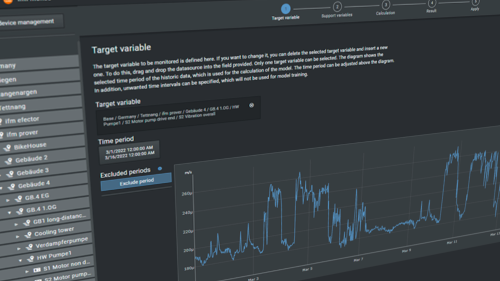

moneo SmartLimitWatcher generates dynamic thresholds based on the status of the process being monitored. It automatically issues alarms and warnings at an early stage as soon as the status of the monitored variables changes – anomalies of a critical process variable occur.

moneo PatternMonitor:

Intelligent detection of unwanted process changes.

moneo PatternMonitor identifies structural changes in a critical variable. Depending on the configuration, it detects trends, changes in volatility and level changes and automatically generates alarms so that you can take appropriate action at an early stage.

Differences and possible combinations

moneo SmartLimitWatcher is suitable for ...

- multi-stage or controlled processes

- focussing on entire machines and plants

Operating principle

- The entire system is modelled to detect anomalies of the target variable

moneo PatternMonitor is suitable for ...

- monitoring single-stage stationary, continuous processes and plants

- focussing on individual parameters of machines and plants

Operating principle

- Identification of structural changes in critical process values

Advantages of

moneo DataScience Toolbox vs. data science projects

| Implementation: moneo DataScience Toolbox |

vs | Implementation: your own data science project |

||

|---|---|---|---|---|

|

Easy-to-use tool also suitable for maintenance teams without data science skills |

Access to data scientists necessary (expensive, 20k*) |

|||

|

Automated data preparation and guided AI training |

In-house project structure required |

|||

|

Integrated and scalable solution when combined with other moneo modules |

Manual data acquisition and processing process required |

|||

|

Suitability for a wide range of applications and quick solution availability |

Minimum project duration approx. 3- 6 months |

|||

|

Customisable and extensible – from beginner to professional level |

Tailored solutions are often not easily transferable and applicable |

|||

|

Excellent price-to-performance ratio |

Increased investment risk due to limited scalability |