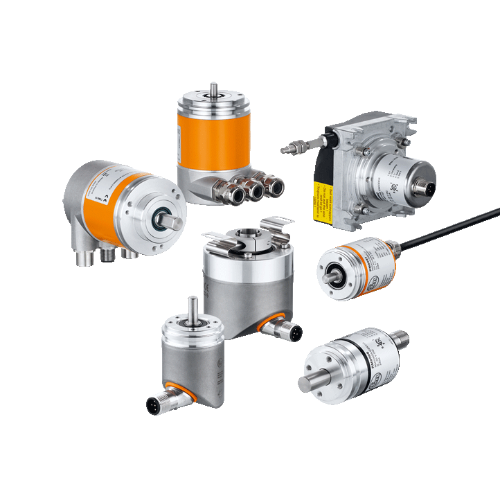

- Encoders

- Absolute encoders

Absolute encoders

Absolute encoders provide an absolute numerical value for each angular position- either for only one revolution (singleturn) or for multiple shaft revolutions (multiturn):

Absolute encoders using optical technology transmit light through gaps that have been etched into a coated glass disc. Pulses are generated as the beams are broken.

Absolute encoders using magnetic technology generate pulses by rotating a magnet over a sensing chip (Hall sensor) and measuring the change in the field (Hall effect).

With absolute encoders, the absolute position value of the shaft is available even after power loss. Unlike conventional incremental encoders, they require no homing run to the start or home position after a power failure.

Versions

| Type | HousingØ [mm] | Solid shaftØ[mm] | Hollow shaftØ [mm] | Resolution | Features |

|---|---|---|---|---|---|

Absolute multiturn |

36.5 mm 42 mm 58 mm |

6 mm 10 mm |

12 mm 15 mm |

24-bit 25-bit 31-bit |

• Resolution and signal can be set • Profibus, ProfiNet DeviceNet, SSI, CANopen & IO-Link interface |

Absolute singleturn |

58 mm | 6 mm 10 mm |

- | 13-bit | • Resolution and signal can be set • Profibus and CAN interface |

Absolute encoders are available with parallel, serial or fieldbus outputs to transmit shaft position data.

- Absolute encoders with parallel outputs require an output for each bit of information. For example, an absolute encoder with a 12-bit parallel output would require twelve separate outputs to transmit the data. This encoder would have a resolution of 4096.

- Data on the position of the encoder can also be transferred via the synchronous serial interface (SSI).

Absolute multiturn encoders

These encoder types determine the exact position by looking at the code on the disc over multiple rotations.

More precisely, this code consists of the location on the disc (resolution) and the location of the gear train (revolutions). This makes multiturn encoders ideal for angle measurements as well as for linear measurements and distances. Type versions with Devicenet, Profinet, Profibus, CANopen, Ethernet IP and EtherCAT interfaces are provided.

Multiturn encoders can also be operated with IO-Link.The benefit of this: Using an IO-Link master, one encoder can be used for multiple fieldbuses. This reduces storage costs. In addition, inexpensive standard cables can be used. Once the IO-Link infrastructure is set up, wiring complexity and susceptibility to failure are greatly reduced.

Absolute singleturn encoders

These encoders provide a unique coded value for each position on the shaft.

They are used in applications where the shaft does not rotate more than 360°.

Versions with Profibus or CAN interface are available.

All incremental encoders from ifm operate like absolute singleturn encoders when used on IO-Link. They detect and save their position value even if power fails.