From vibration monitoring to real-time maintenance

Insights

Imagine having permanent real-time visibility into the condition and processes of your machines.

Planning

What if you could address machine and system problems in their early stages and plan maintenance activities proactively?

Safety

Imagine you could maximise plant availability and machine health and prevent costly surprises.

Optimisation

What if you could ensure process continuity or even optimise the process of your installation by recording vibration data?

Common industrial maintenance strategies

Reactive maintenance

Reactive maintenance is a strategy where maintenance tasks are performed only after a failure has occurred. No preventive actions are taken. Maintenance work is only completed in reaction to a breakdown. While this strategy may be suitable in some cases, it is generally not cost-effective (high total cost of ownership).

Disadvantages:

- Long downtimes

- Higher repair costs

Preventive maintenance

Preventive maintenance consists of performing periodic maintenance tasks in a planned and scheduled manner regardless of whether a fault has occurred or not. The objective is to identify and fix potential problems early in order to minimise downtime. This can include inspecting, cleaning, lubricating or replacing parts. Maintenance schedules are usually recommended by manufacturers or based on historical data.

Disadvantages:

- Machine downtimes, even if not necessary

Condition-based or real-time maintenance

This strategy involves monitoring the current status of a system through the use of vibration sensors or other diagnostic tools. The data obtained can be used to determine maintenance requirements. Maintenance is performed only when the condition of the system meets or exceeds certain predefined criteria.

Advantages:

- Optimal use of resources

- Reduces unnecessary maintenance

Prediction

Equipment/Machine failures are usual gradual. Different status parameters can indicate a deterioration. Vibration condition monitoring opens up the ability to make predictions.

Vibration and friction occur long before a system/machine fails. Through active monitoring, potential damage can be detected months in advance. Weeks to days before the system fails, increased noise and heat occur.

Application matrix

In this application matrix, we provide system recommendations based on the application-specific vibration behaviour and drawing on decades of experience of our application engineers. In addition, it is necessary to take the customer-specific monitoring requirements into account, e.g. with regard to interfaces, functions and overall system requirements. For this purpose, please refer to the relevant product information pages or approach our customer support team.

| Machine classification | Application | Single-point measurement | Multi-point measurement | IO-Link | Programmable diagnostic electronics |

|

|---|---|---|---|---|---|---|

| VK / VT | VN / VW | VVB | VSE | |||

Type 1 - simple machines

|

|

|

||||

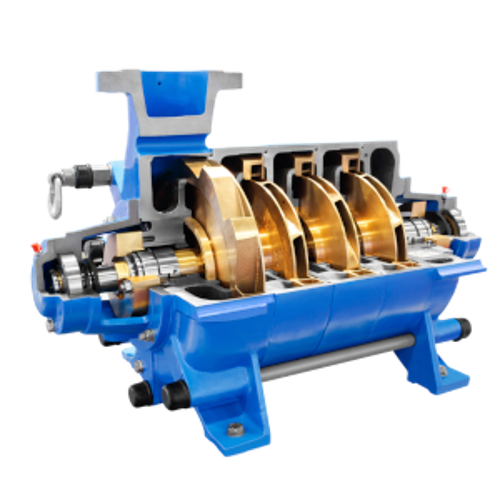

Type 2 - process machines

|

High process forces

|

|

||||

Very high process forces *

|

|

|||||

Type 3 - complex machines

|

|

|

* Use VVB only for process force monitoring