- Automotive Industry

- Battery

Emobility – The future is electric

The transition from combustion engines to hybrid and electric vehicles is necessary for the improved future of the planet. Emobility will play a pivotal role in that transition, but it provides unique production challenges for automotive manufacturers.

The transition from gas powered vehicles to full electrification will take decades, and hybrid vehicles will be an important part of that transition. Manufacturers have to prepare for producing all of these vehicles, meaning their production lines have to become more flexible and easy to changeover as consumer trends evolve.

With Emobility solutions from ifm, you can continually create high quality products through this transition.

Improved machine availability

Plan and predict long-term maintenance to minimize the risk of unplanned downtimes. Keep plant maintenance in view at all times with systems for vibration analysis and precise digital data via IO-Link.

Improved product quality

With more production data available at more points of collection through connected sensors, automotive manufacturers can increase quality control steps throughout production. Identify bad parts before they move further down the production line.

Improved machine performance

By collecting more accurate sensor data in real-time, you are alerted immediately of any drift in the production process. This allows you to make corrections immediately and gain better insight into process parameters that produce high quality products.

Use cases

Electric motor manufacturing

Replacing combustion engines, the electric motor needs to be carefully constructed to meet high quality and safety standards in final vehicles.

Battery recycling

Recycling raw material components for use in new batteries helps reduce the overall emissions of EV production and helps to ensure that there are enough minerals to meet consumer demand. Automation will ensure this process is repeatable at scale.

Hydrogen and fuel cell manufacturing

Hydrogen fuel cells have high potential for transitioning commercial vehicles away from fossil fuels, as their weight makes electric motors a challenge. ifm solutions are often used in hydrogen and fuel cell manufacturing processes during quality checks at inspection stations.

Charging infrastructure

The future of electrication depends on a connected and distributed network of charging stations over long distances. ifm products are helping manufacturers create the EV fast-charging station infrastructure necessary to power the future of heavy duty electric vehicles and passenger cars.

IO-Link provides a flexible communication protocol for connecting smart sensors. The purely digital signal provides a more accurate resolution compared to traditional analog technology.

Vision sensors combine object recognition and inspection in one device. This allows you to identify defective parts earlier in the production process.

Pressure sensors continuously monitor system pressure and provide real-time insights into the performance of equipment during production. Identify pressure peaks or valleys in real-time that could impact product quality.

Flow sensors are critical for real-time monitoring of flow rate, totalized flow, and media temperature in one device over IO-Link.

Temperature sensors provide real-time monitoring of the media or surface temperature for consistent measurement throughout production. They are rigorously tested to prevent moisture ingress and other common causes of sensor failures.

Image-based code readers enable serialized production tracking over IO-Link to enhance quality control systems.

Laser distance sensors use time-of-flight technology to detect targets, regardless of color, material, reflectivity, or angle.

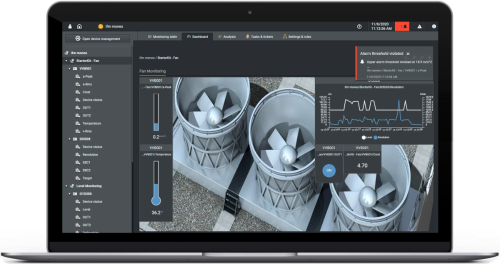

moneo|software seamlessly visualizes machine health, trends and stores process data, and triggers alarm notifications. Built for easy integration and setup, get started in hours, not weeks.

Gain a competitive edge

As electric vehicles become the future of the automotive industry, using fixed production lines will be too expensive to adapt and maintain as technology progresses. Implementing flexible automation solutions from the beginning will allow manufacturers to act quickly as consumer demands evolve during this transition period. Partner with suppliers that are working with your future needs in mind.