Food & beverage automation: improving quality in real-time

For food and beverage manufacturers, product quality is at the core of their operations. Safety and consistency during production are key to maintaining or improving quality that builds brand reputation and trust with consumers. How can manufacturers improve both safety and consistency? Automation technology enhances process control and increases machine availability, so you can feel confident that only the highest quality is reaching customers.

Food manufacturers are successfully using real-time machine health and process data to eliminate both planned and unplanned stops. This is helping them meet increasing consumer expectations and contain rising costs. Smarter design is accelerating integration of new technology, reducing instrument failures, and increasing efficiency and safety of cleaning processes.

Improve product quality

Protect your brand through improved food safety and batch consistency. Automation reduces the risk of human errors that can impact quality.

Improve machine availability

Reduce planned stops and eliminate unplanned stops with innovative technology to reduce changeovers, instrumentation failure, and cleaning cycle time.

Achieve sustainability goals

Gain visibility to process inefficiencies causing excess energy and water consumption. This allows you to benchmark and quantify a reduction in environmental impact.

Improve food safety

Maintaining food safety is the most important thing during food and beverage production. From raw ingredients to finished goods, strict process control and traceability throughout production helps a manufacturer build trust with customers by ensuring only safe products make it to store shelves. Automation can help to continuously improve processes through:

- Reliable and repeatable instrumentation

- Automatic traceability protocols

- Improved cleaning processes

If process sensors drift and measurements are inaccurate, this can result in either scrapped product or unsafe products continuing on to consumers. Reliable, repeatable, and accurate process sensors build confidence in your measurements, and provide verification that cleaning processes are fully completed between batches.

Eliminate or reduce recalls

The losses associated with recalls can be significant. Traceability is important to maintaining a safe food supply of:

- Raw ingredients

- Food or beverages during production

- Finished products during packaging and shipping

With automated traceability systems, you can ensure production steps are recorded as verification in the event of a potential recall investigation. Automated temperature monitoring during cold storage can help verify that finished goods remained in a safe climate-controlled environment during packaging and shipping.

Improve batch consistency

High quality products are manufactured with reliable consistency from batch to batch. This ensures that no matter where or when a customer eats or drinks a product, they experience the same flavors and build trust with a brand. Reduce common causes of failure with instrumentation that:

- Uses a pure digital signal over IO-Link

- Undergoes rigorous construction & testing

- Increases points of measurement

By implementing more robust process instruments that are less prone to common causes of failure, you can feel confident in the accuracy of your measurements and gain additional insight from more data points during production. Higher resolution of a digital signal over IO-Link allows for tighter control during production to ensure consistency every time.

Reduce planned downtime

Line changeovers and cleaning processes can cause significant downtime, even if planned. With the rise of small, seasonal batch recipes and mass customization, reducing changeover time is important for maintaining efficiency. Automation can help to reduce:

- Clean-In-Place (CIP) cycle times

- Integration time of new technology

- Time-based calibration costs

- Service repair time

Reduction in cleaning cycle time, without sacrificing quality, can help improve machine availability. With more intuitive solutions designed for easy integration, it's now significantly easier and faster to integrate new technology than ever before.

Eliminate unplanned downtime

While reducing changeovers and cleaning processes can help with reducing planned downtime of your machinery, eliminating unplanned stops is essential to maintaining high efficiency of plant operations. Pure digital signals over IO-Link reduce inaccuracies associated with analog conversions, providing better process control. This helps to reduce:

- Bottleneck machine failures

- Instrumentation failures

- Raw material shortages

- Human error in manual processes

Connected machines can identify when inventory is running low and prompt automatic refills or reorders of ingredients. With high performance smart sensors at a better price point, you can implement more points of monitoring to gain additional insight into your processes.

Reduce resource consumption

Customers are increasingly asking producers to quantify and publicize the impact of their manufacturing processes on the enviroment. Automation of food and beverage production allows you to capture more data than ever before. You can use this data to benchmark current consumption and set goals for annual reductions. Smart sensors and connected machines help you to:

- Optimize water consumption

- Optimize energy usage

- Optimize chemical usage

With automated monitoring over IO-Link, manufacturers can send their data directly to higher level software systems while bypassing the PLC. This allows companies to avoid interfering with machine controls in order to send the data through an IIoT connection. Then, producers can reliably quantify their data for analysis and reporting by sending it directly to those that need it.

Increase sustainability

Calcuating an overall environmental impact requires monitoring of different processes within your facility. Automation can help with monitoring of:

- Wastewaster from industrial processes

- Byproducts or chemical waste

- Total carbon emission

Whether you need to quantify your carbon impact to hit corporate sustainability targets or meet regulatory compliance, automation and connected machines are helping you gain insight into your machines and processes in real-time to achieveyour goals. Efficient treatment and disposal of wastewater or byproducts from industrial processes helps you to meet environmental regulations. Automating the recordkeeping of this historical data increases efficiency in reporting.

IO-Link is the foundation of smart manufacturing. It is a flexible communication protocol that can send multiple process values over one wire, increasing access to real-time production data.

Pressure sensors or level sensors provide high degrees of accuracy and reliability for optimal machine design. Designed to withstand caustic cleaning solutions and washdown, they are rigorously tested to prevent moisture ingress and other common causes of sensor failures.

Conductivity sensors provide real-time measurements that allow you to monitor skid health in a variety of applications. The price performance ratio allows you to implement multiple data points on a machine for increased insight into processes.

Temperature sensors provide real-time monitoring of the media. Designed to withstand caustic cleaning solutions and washdown, they are rigorously tested to prevent moisture ingress and other common causes of sensor failures.

Flow sensors are critical for monitoring flow rate, totalizing functionality, and media temperature in real time. Receive all of these process values from one sensor over IO-Link for real-time monitoring of your batch during production.

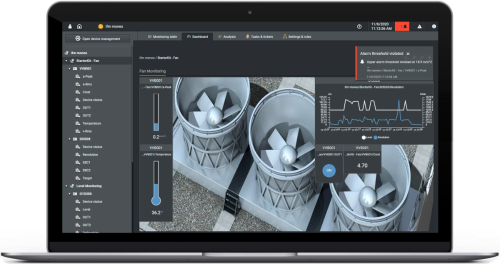

moneo|software seamlessly visualize machine health, trend and store process data, and implement alarms. Built for easy integration and setup, get started in hours, not weeks.

Preparing for the future of food & beverage production

As technology advances, we will see even more integration of artificial intelligence, IIoT, and robotics in food and beverage automation. The tools and software available today are easily accessible, user-friendly, and designed to integrate seamlessly into existing infrastructure.

Food and beverage manufacturing can experience more streamlined operations, enhanced product quality, and reduced environmental impact by implementing Industry 4.0 initiatives. Manufacturers can future-proof their business now to ensure that they are prepared to easily integrate new technologies as they develop. Get started with a fast proof of concept.