The greenhouse of the future

More sustainable and efficient with ifm automation technologies

| System transparency | Quick and easy set-up | Efficiency increase |

Results

- All relevant measured values for the indoor farm can be easily monitored, ensuring high product quality and less rejected produce

- Efficient connection of the sensors via IO-Link

- Commissioning becomes faster and more efficient

- Scalable systems thanks to technological support from ifm

The challenge

For the plant growth to be accurately controlled and in order to achieve a high degree of automation, a large number of variables must be measured in an indoor farm. On the basis of these measured values, the system can then be optimised to maximise crop yield.

Modern vertical farms require a system combination of hardware, automation, intelligent controllers and sensors. The process control and the data acquisition are becoming increasingly complex. A conventional system design requires a considerable amount of programming and integration.

Each indoor farm has hundreds of I/O signals on its individual vertically stacked layers, which used to be routed back separately to the controller in the past. Accordingly, maintenance work, troubleshooting and the replacement of sensors were very time-consuming. Better and smarter solutions were required for the new projects.

The solution – why ifm?

A variety of different process sensors are used for indoor farms: flow meters for water and nutrient dosing, pressure sensors for the water level, conductivity to check the concentration of minerals, and sensors to control the pressure at the pumps.

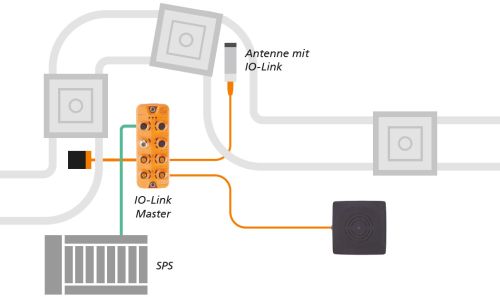

Connecting all sensors via IO-Link field modules reduces the complexity of process control and makes more data available from each sensor, thus reducing the overall need for sensors. Recipe changes and design adaptations due to ongoing innovations are easy to implement using digital communication. The entire set-up process from physical wiring to integration and programming has thus become much more efficient.

With the help of IO-Link technology, customers are now able to standardise their systems and individual modules so that vertical farms can be scaled very easily. Hence, future projects can be implemented much more easily, while also accelerating set-up.

Customers see ifm as a technology partner who is able to help with improving all of their applications. What is more, sensors from ifm can be used in the harvesting process, which is also automated: image processing, position sensors and RFID are just a few examples – and here, too, ifm can of course provide the best possible support.