Smart and easy wiring with IO-Link

OEM achieves cost and time savings of up to 60 % during set-up

| 30 % cost reduction for instrumentation |

60 % reduction of installation time |

250 % ROI after one year |

Results

- Preparing for Industry 4.0 with IO-Link products

- Measurable cost savings of up to 30% per machine type

- Reduction of installation and commissioning time by 60%

- Total savings per year: €100,000

The challenge

The company supplies customised plants for various production processes. In the food and beverage industry, plants must comply with strict guidelines such as the 3A SSI or the EHEDG standards. In compliance with these guidelines, production plants are designed hygienically to ensure the greatest possible product safety.

For OEMs who manufacture many individual machines according to specific customer requirements, the versatility and ease of installation of the automation components they use is a decisive competitive advantage. However, customisations that go beyond general market requirements present manufacturers with numerous challenges in their projects. Efficiency, short commissioning times, plant safety and reliability are absolutely essential. The previous automation concept based on parallel wiring no longer met these requirements due to low flexibility and high installation costs.

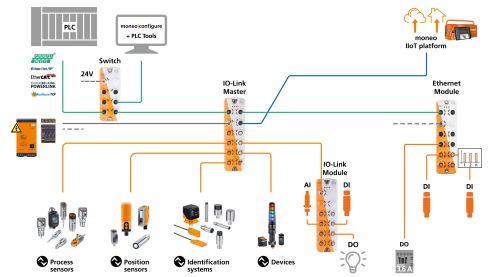

System overview IO-Link

The solution – why ifm?

By using IO-Link products from ifm, the company manages to ensure higher efficiency, lower costs and more flexibility, while at the same time being able to work in a standardised manner. The ifm sales team analysed the actual situation on site and developed a network architecture individually adapted to the customer requirements. The IO link master plays a central role in this: because it provides for a simple and quick adaptation of the wiring to different machine types, which reduces both the installation and wiring costs. With its IP69K protection class, the IO-Link master can be used directly in the field; local junction boxes are not required.

Digital communication via standard cables without shielding means that fewer cables are used than before – this facilitates cleaning. Installation is fast and simple thanks to the “plug & play” principle. This is made possible by an M12 connection which guarantees secure and correct wiring and eliminates potential sources of error.

Furthermore, analogue signals do not need to be scaled, analogue input cards are no longer required, and the control element becomes leaner. In addition to optimising the network architecture, ifm’s experts offer customers training in the use of IO-Link to make the changeover to digital technology even easier.