Data center environmental monitoring: Modular solutions that scale

The rapid adoption of Generative Artificial Intelligence (Gen AI) is driving demand for more data center capacity. Whether building a new facility or retrofitting existing infrastructure, data centers need more agile environmental monitoring of cooling systems to accommodate the rise in the thermal density of new server GPUs.

The fast pace of industry growth has moved faster than industry standards, leading to supply chain constraints and reduced scalability of innovative cooling systems. Many data centers must now accommodate multiple cooling system technologies and ensure optimal flow to server racks of varying thermal density within a given facility. To increase scalability, they need equipment and components that are modular, interchangeable, and futureproof.

Benefits of data center cooling automation

Build new data centers faster and retrofit existing facilities quicker with equipment that is simpler to set up and program.

More accurate data from a digital signal improves cooling system performance, reduces downtime, and enhances digital twin predictive modeling.

With innovation moving faster than industry standards, reduce equipment design risk and safeguard your supply chain with future-proof technologies from stable suppliers.

Real-time monitoring of cooling systems improves efficiency and reduces excessive energy and water consumption.

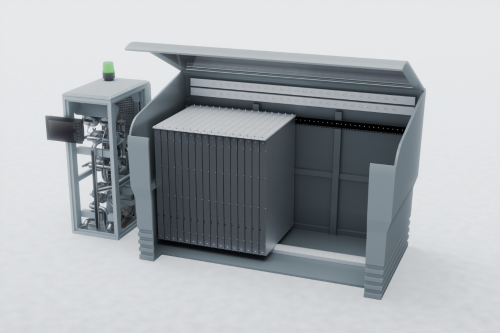

Accelerate deployment of new data centers

Bring new data centers online faster by leveraging ifm's modular solutions for cooling system monitoring. Reduce commissioning time with this approach by:

- Reducing installation and validation time

- Improving access to process data

- Reducing the risk of human errors

Dramatically reduce installation time and complexity of data center cooling systems with ifm's plug-and-work solutions. With access to more process data via IO-Link, you can consolidate sensors and wiring to reduce setup time and labor.

Improve the adaptability of critical equipment

Accommodate optimal cooling requirement variations within a data center facility with a flexible system that leverages innovative technologies such as:

Server racks installed side-by-side today have mixed thermal density, requiring dynamic cooling systems. By prioritizing modular components, you improve flexibility to adapt cooling systems quickly as thermal density increases.

Improve scalability

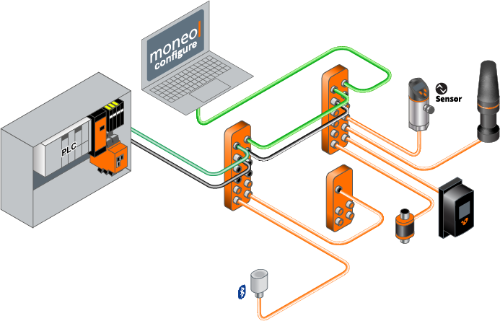

To improve the scalability of equipment and monitoring systems, reduce or eliminate reliance on proprietary technologies, manual scaling of analog sensors, and extensive wiring of inputs and outputs. Consolidating sensors and wiring reduces the number of components and suppliers. This makes it easier to copy building designs and reduce maintenance and inventory costs. Ensure that new systems scale quickly with IO-Link.

Explore data center environmental monitoring technologies that scale easily with your deployment timeline.

Improve cooling system performance

Purely digital sensor data provide superior accuracy and reliability by eliminating the inherent conversion loss of analog signals. Improving measurements helps to fine-tune cooling systems for maximum efficiency and ensures that servers operate optimally. This reduces thermal throttling, improves coolant quality, and increases measurement confidence.

Reduce server downtime

Identify subtle changes in equipment performance, from coolant quality degradation to increased pump vibration, before they are critical. Continuous asset health monitoring trends data over time to enable:

- Advanced predictive diagnostic capabilities

- Immediate intervention

- Improved cooling capacity planning

Improved sensor data quality enables more accurate digital twins to predict and prevent unexpected outages. With real-time data and early-warning systems, you shorten reaction time and reduce potential damage, helping to extend equipment lifespan.

Reduce threats of thermal throttling

Accurate and reliable measurements are essential to maintaining optimal thermal conditions for mixed-density server racks. With more accurate sensors at affordable prices, the number of measurement points throughout cooling systems can be increased to optimize computing resources more precisely and operate at full capacity.

Improve coolant quality

As thermal density requirements increase, many data centers adopt innovative liquid cooling methods, such as liquid-to-air coolant distribution units (CDUs), liquid-to-liquid CDUs, and liquid immersion systems. Data centers can monitor coolant health in real time by implementing oil humidity, flow, or conductivity sensors. With continuous insight into coolant degradation, facilities can optimize maintenance schedules and keep machines running at peak performance even longer.

Futureproof cooling equipment

As new server GPUs launch faster than ever, data centers risk relying on outdated cooling systems in just a few years. Improve resiliency of equipment and system design with IO-Link by:

- Simplifying reconfiguration

- Increasing interoperability of components

- Leveraging automatic parameterization

When compared to traditional analog infrastructure, system reconfiguration is not as burdensome with IO-Link. The inherent flexibility and modularity of the technology mitigates equipment design risk by making it easier than ever to add new functionality to existing machines. When future equipment requirements are uncertain, IO-Link reduces risk by keeping cooling systems flexible enough to adapt to change.

Resilient supply chain

To scale effectively, partner with a stable supplier that can meet high-volume production demands. With ifm, data centers can improve their supply chain resiliency by choosing a partner with 50 years of experience producing high-quality industrial products.

With hundreds of industrial suppliers committed to the IO-Link consortium, those utilizing IO-Link technology are not locked into a proprietary ecosystem or vendor. This reduces the risk of relying on a single supplier to meet your hardware needs.

As the data center industry expands, it faces more scrutiny from various stakeholders who want to understand the environmental impact. Simplify monitoring of key metrics, including:

- Power Usage Effectiveness (PUE)

- Water Usage Effectiveness (WUE)

- Energy Reuse Factor (ERF)

At the scale of data center energy consumption, even small reductions in waste can have significant financial impacts on monthly operating costs. Simplifying monitoring systems and improving the accuracy of measurements will help data centers meet common environmental goals.

Energy efficiency optimization

Prevent overcooling and thermal throttling with more precise measurements. Identifying inefficiencies immediately reduces energy usage without compromising performance. With more accurate and immediate monitoring solutions, measure power usage effectiveness (PUE) calculations in real time.

Water conservation

Real-time monitoring of water consumption helps identify opportunities for conservation and leaks in the system. More accurate measuring technology improves confidence in Water Usage Effectiveness (WUE) calculations.

Heat reuse opportunities

Data center servers generate significant amounts of heat that need to be discharged. Temperature and flow sensors help assess opportunities for heat reuse, such as heating nearby buildings or powering absorption chillers. Reusing excess heat helps improve metrics such as the Energy Reuse Factor (ERF) and provides a positive financial impact.

Regulatory compliance

Monitoring cooling systems provides the data needed to demonstrate compliance with environmental regulations, avoid penalties, and support corporate sustainability initiatives.

Supply chain decarbonization

Reduce the carbon footprint calculations across the supply chain by partnering with suppliers like ifm that promote sustainability and environmental stewardship through documented responsible sourcing, energy-efficient manufacturing processes, and ethical business practices.

Temperature monitoring

High-precision temperature sensors provide accurate, reliable readings across a facility. They should integrate seamlessly with existing heating and air conditioning systems.

Humidity control

Humidity detection sensors monitor ambient conditions and coolant systems to ensure optimal operating conditions throughout a facility.

Airflow and pressure differentials

Pressure sensors help maintain ideal pressure differentials between hot and cold aisles. Monitoring airflow optimizes cooling efficiency while preventing hot spots.

Coolant quality monitoring

Oil humidity sensors continuously monitor coolant conditions. They provide early warning alerts of contamination or degradation before they impact performance.

Equipment vibration analysis

Vibration sensors detect the four leading causes of equipment fatigue through continual analysis and early intervention.

Key technologies for data center environmental monitoring

Explore all of the best solutions for monitoring data center cooling systems.

IO-Link provides a flexible communication protocol for connecting smart sensors. The purely digital signal provides a more accurate resolution than traditional analog technology.

Level sensors provide high degrees of accuracy and reliability for optimal machine design and are rigorously tested to prevent moisture ingress or other common causes of sensor failures.

Temperature sensors provide real-time media monitoring and are rigorously tested to prevent moisture ingress.

Flow sensors are critical for monitoring flow rate, total flow, and media temperature in real-time via IO-Link communication. Based on your coolant properties, choose the best flow measurement technology.

Oil humidity sensors continuously monitor oil quality by measuring coolants' relative humidity and temperature. Early detection of water in oil allows maintenance to be planned before harm or corrosion to equipment occurs.

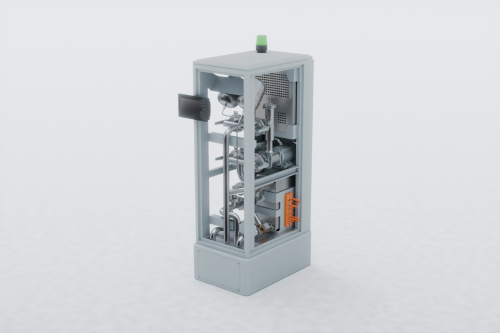

Display controllers simplify the visualization of machine performance. As a modular solution, they combine the functionality of an HMI display, PLC for machine control, and data connection for remote monitoring. You can use any combination of these built-in features.

Vibration sensors offer many ways to monitor machine performance in real time. Select from multiple plug-and-work options with IO-Link technology to monitor the four leading causes of machine failure without any additional programming required.

Air humidity sensors provide a field-mountable solution that reliably measures ambient humidity where it matters most.

Reliable supply chain of modular tools

From sensors to networking and controls, ifm's plug-and-work approach simplifies equipment and reduces compatibility issues. With 50 years of production experience and a focus on same-day shipping, ifm has optimized its supply chain to help you scale and meet customer demand.

Proven reliability in demanding environments

ifm sensors and monitoring systems are engineered for durability against challenging industrial conditions and can accommodate various coolant media found in data center facilities.

Expert consultation and support

ifm's team of specialists understands the unique challenges of data center environmental monitoring. Specialists help you design the optimal monitoring solution for your equipment and offer ongoing technical support at no additional charge.

Partnership for long-term success

The ifm commitment to innovation ensures your monitoring systems will continue to meet your needs as technology and standards evolve. Receive world-class support that aims to help you succeed in your business.

Preparing for the future

Data center environmental monitoring increases speed to market, increases equipment efficiency, and helps achieve sustainability goals. Data centers can address challenges and achieve significant benefits by leveraging IO-Link technology, plug-and-work sensors, and real-time monitoring capabilities. ifm's innovative solutions can help data centers gain a competitive advantage.

Discover how ifm solutions can help you build faster, operate more efficiently, and meet your sustainability goals.