Ground support equipment automation

Ground support equipment automation is the use of technologies like automated systems and robotics to enhance the safety, efficiency, and continuity of airport operations. From collecting real-time data to implementing smarter collision avoidance systems, there are many robust solutions to enhance the performance and efficiency of ground support operations. Innovative technologies are improving insight into these critical pieces of equipment to increase safety and availability.

Benefits of ground support equipment automation

Increase safety with collision avoidance

Enhance accident prevention with smart object detection and classification, and collision avoidance systems on ground support equipment.

Improve operational efficiency

Optimize operational efficiency by increasing access to machine data of ground support operations.

Reduce total cost of ownership

Flexible software, simplified controls, and automated guidance systems reduce overall build time, hardware and labor costs, and accidents.

Automated collision avoidance solutions

Collision avoidance systems improve decision-making for operators when a plane comes into view. These systems use:

- Automated aircraft approach

- Object detection

- Object classification

This advanced functionality enhances the reliability of aircraft proximity detection, consolidates sensor signal data, and increases visual feedback with an HMI display. These three parts of collision avoidance systems need to function reliably in all weather conditions and integrate easily into vehicles with moving components, such as extendable conveyor belts or deicer booms.

Improve worker safety

After implementing visual feedback with depth-sensing cameras, the next level of automation includes object classification using embedded artificial intelligence (AI) solutions. Increase safety by discerning people from equipment on the tarmac using algorithms that identify the risk level of various objects. Even simple object recognition by shape and size helps operators make more informed decisions quickly. Some systems can even predict the behavior of objects after classification, such as human walking patterns. Object classification provides additional situational awareness for operators to improve safety on the ground.

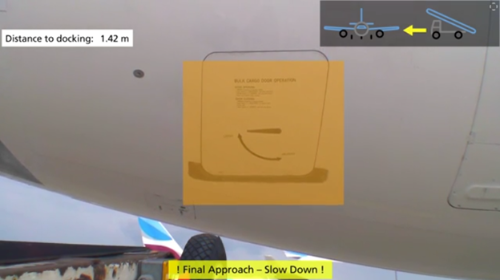

Automated aircraft approach

When ground support equipment approaches an aircraft, the operator must be precise and deliberate. Colliding with the hull has significant consequences. Ground support equipment can leverage innovative technology to:

- Slow the approaching vehicle

- Automate vehicle guidance into position

Automating the aircraft approach reduces the risk of damage and accelerates plane turnaround time (TAT). Radar sensors provide a wide field of view and durable housing to ensure reliable depth perception at varying angles and speeds. This provides critical proximity data for machines to enter “turtle” or “snail” modes in the approach. The depth sensing ranges can help an operator guide belt loaders or stairs to aircraft openings, or even automate the guidance into position.

Enhance the operator experience

Visual feedback significantly improves the operator experience by providing proximity ranges and visibility to blind spots. Having one centralized interface for managing all real-time data and controls reduces operator errors and increases efficiency. Enhance the operator experience by integrating:

- Vehicle control systems

- 3D camera feeds

- Radar sensor information

In an atmosphere where engine noise may interfere with acoustic warnings, visual displays provide operators with an important tool to make better decisions.

Simplify machine controls

Reducing complexity helps operators quickly make more informed decisions that impact safety and efficiency. Integrated HMI controllers centralize machine control and real-time data in one display. Operators can access:

- Visualization of vehicle information

- Multiple camera views for obstacle detection

- Vehicle controls

This streamlines operations by consolidating buttons, gauges, and indicator lights into one interface. An intuitive display also reduces training time and potential distractions.

Improve Turn Around Time (TAT)

Automation solutions significantly improve daily throughput when an aircraft enters a holding bay. These solutions provide data for ground support operators that optimize maintenance and refills to maintain tight aircraft schedules.

Increased insight into flow rate, tank level, and temperature improves ground support efficiency by:

-

Verifying the correct application of deicing solution

-

Ensuring lavatory trucks are fully emptied

-

Optimizing cargo loading and unloading time

Robust hardware minimizes unplanned downtime. Plug-and-work technologies expedite planned maintenance.

Eliminate manual operations risks

Today, ground support equipment performance relies heavily on operator experience. Collecting real-time operational data increases efficiency, optimizes logistics, and ensures compliance with new safety standards.

On a deicer, monitoring critical information like flow rate and tank level ensures a complete application each time by:

-

Measuring the correct amount

-

Reducing waste of expensive glycol solutions

-

Optimizing tank refill schedules

An incomplete application of deicing fluid is a safety risk and an overapplication wastes resources. Measuring critical process variables enables operators to refill between peak times and identify more efficient machines. Over time, this data optimizes maintenance schedules by forecasting total usage throughout the season.

Reduce production costs

Reduce hardware and software costs with more flexible and modular technology:

- Hardened PLCs provide one platform with multiple communication protocols and simplified software. This setup increases compatibility, reduces specialized programming, and reduces manual wiring.

- HMI controllers simplify machine controls. This reduces the risk of supply chain disruptions for various physical components including gauges, buttons, and lights.

- Decentralized I/O modules simplify installation by reducing wiring complexity. This reduces the cost of replacement parts, parameterization, and maintenance over the life of the machine.

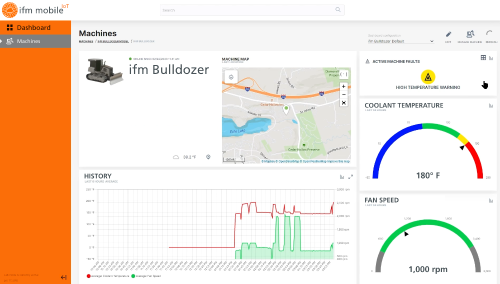

Remote monitoring and maintenance

Remote capabilities allow users to monitor machine conditions and troubleshoot from a distance. Operators can optimize equipment parameters in changing conditions remotely. Fleet managers or machine builders can access machine data to diagnose and schedule repairs. They can order replacement parts before sending workers onsite to optimize service call logistics. This flexibility:

- Minimizes planned and unplanned downtime

- Increases service call efficiency

- Provides new contract opportunities.

With continuous monitoring, maintenance and regulatory compliance are more efficient.

Futureproof machines

Prepare for the future by transitioning to hardware and software that prioritizes:

- Flexibility

- Modularity

- Interoperability

Simplified controls with standard software ensure adding new functionality to ground support equipment is possible without a full machine redesign. Designed for interoperability, standard software reduces the burden of integrating different programming languages. Robust HMI controllers and hardened PLCs with powerful computing power, stability, and reliability provide flexible system architecture for many applications.

Hardened PLCs for mobile machines require high-power control electronics to process many inputs and outputs. ifm's product portfolio provides more computing power, stability, and reliability than ever before. CODESYS 3.5 provides easy integration of control functions.

HMI controllers are programmable graphic displays for controlling, parameterizing, and operating mobile machines and systems. They operate in combination with a mobile controller or as a stand-alone solution. The data and device functions are reliably transmitted via the CAN, Ethernet, and USB interfaces.

ioControl is a decentralized I/O module connected to the controller via CAN. Reduce wire harness complexity, add functionality, and use an integrated two-color LED display for the most important system messages.

3D mobile camera systems enable advanced collision avoidance systems to increase the safety of ground support vehicles.

Radar sensors are powerful options for collision avoidance systems on ground support equipment. They also provide vehicle position, height, speed, and distance data, regardless of fog, steam, or smoke.

Telematics enables secure, remote access to machines through an Ethernet gateway. With ifm's Telematics and MioT suite, improve overall equipment efficiency with real-time serviceability of ground support equipment.

IO-Link provides a flexible communication protocol for connecting smart sensors. As part of an open consortium, it is technology-agnostic. The purely digital signal provides a more accurate resolution than traditional analog technology.

Preparing for the future of ground support equipment

Innovative technologies are improving ground support operations by increasing safety, reducing complexity and costs, and optimizing efficiency. Better data leads to better forecasts and optimized maintenance schedules that improve aircraft TAT.

Gain key insights into machine conditions with real-time data to empower operators and fleet management to make more informed decisions. Find out how to benefit from increased flexibility and interoperability of hardware and software for ground support vehicles by partnering with ifm.