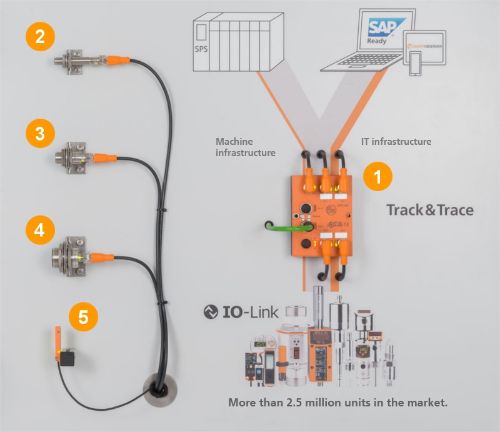

- The Y path

- Track & Trace

Track & Trace with the Y path from ifm

From production to logistics - reduce the fault rate in production! Traceability is used to keep track and ensure the quality of all production parameters: when, where and in what conditions was your product made.

Through timely monitoring of quality key figures, product traceability can reduce quality-related downtime. This involves an increase of the First Pass Yield (FPY) as well as a reduction of internal nonconformity costs. In addition, product traceability provides protection against recourse claims in case of recall actions.

Reports

- Period, production date

- Product type (article number)

- Product series (lot number)

- Production part (part number), parts used (batch related)

Recording of all product-related data via:

- Barcode or data matrix code

- Chip card

- Magnetic cards

- RFID, etc.

Traceability in logistics

- Automatic recording of all goods at any time, e.g. by means of RFID

- Avoidance of inventory errors and optimisation of stock capacity and inventories

- Automatic target/actual comparison between inventory and order or delivery

- Complete image of the real world in the system world

Application example: Track & Trace

From production to logistics - keep an eye on your production and reduce the fault rate.