IO-Link: worldwide open communication standard

Higher performance. Less effort.

IO-Link sensors from ifm open up completely new possibilities for the user. From easy and quick setup to additionally available machine monitoring data to process transparency from the machine level to the ERP software: IO-Link offers convincing efficiency gains and cost savings. See for yourself!

These results were achieved by customers who previously used standard parallel wiring of analogue sensors, and were primarily driven by significantly reduced installation times, less components needed and easier integration into the controller.

IO-Link has been developed by leading sensor, actuator and control manufacturers. The result is a standardised and fieldbus independent interface for automation. This provides the user with point-to-point connections without complex addressing.

Easy setup, fast sensor replacement

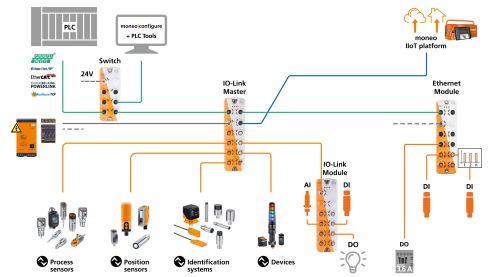

IO-Link devices are simply e.g. connected via an M12 connector. Malfunctions due to incorrect wiring are therefore excluded. Since standard industrial cables can be used for data transmission, the variance of the required cables is reduced. In addition, only one cable has to lead back to the PLC and thanks to IP69K, many IO-Link masters can be used directly in the field.

If an IO-Link master is used, it stores all parameters of the connected sensors. If a sensor is later replaced with an identical unit, the stored parameters are automatically written to the new sensor. Looking up the required sensor settings is not necessary.

This convenient plug & play replacement is made possible by the unique device identification in the vendor and device IDs: With IO-Link the devices can be checked. This ensures that devices are not replaced by unsuitable units.

Exact, interference-proof transmission of measured values

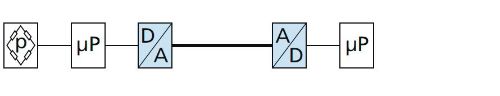

The measured values of conventional sensors are converted several times into digital and analogue data before the final evaluation in the PLC, resulting in the loss of the exact measured values. IO-Link transmits data in a purely digital form based on a 24 V signal and is thus conversion and loss-free.

In addition, the signal transmission is insensitive to external influence. Screened cables and associated grounding are no longer necessary; the data can be transferred via industry-standard cables. Even expensive analogue input cards are no longer needed with the new technology.

Hygienic pressure sensors from ifm continuously detect the level in the pressure tanks. In the past, conversion losses and EMC interference during the analogue signal transmission of the level caused inaccuracies. Thanks to the purely digital transmission of the measured values by means of IO-link, the exact measured value is now transmitted to the controller.

Controller and fieldbus independent

Via IO-Link masters, IO-Link devices can be integrated into almost any infrastructure of fieldbus and control systems, providing interfaces to PROFINET, EtherNet/IP or AS-i, among others. Function blocks of the PLC simplify programming. IO-Link has been developed as an open standard by leading manufacturers from the automation industry and is continually improved. It is even possible to connect actuators such as valve terminals to IO-Link masters. The result is a more flexible and reduced plant infrastructure.

Several measured values in one unit

In applications such as cooling circuits, several process values are often detected to ensure exact process control. Consequently, a conventional measuring point includes several sensors, e.g. to detect the flow rate, the total quantity and the temperature. IO-Link sensors can measure and digitally transmit more than one process value. A flow sensor with IO-Link would be capable of precisely detecting all three values in one unit and transmitting them digitally via a standard 3-wire cable. This significantly reduces the costs for configuration, installation and storage of replacement sensors.

Remote access to sensor parameters

IO-Link device parameters can be changed via parameter setting software such as moneo configure. This allows fast adjustments and reduces downtime. IO-Link sensors can be locked via the operating keys on the sensor or remotely via the software. The lock can not be deactivated without the software, ruling out conscious or unconscious parameter changes on the sensor. The moneo configure software allows users to save device settings and create setting protocols.

Condition monitoring / diagnostics

With IO-Link, the transfer of process and service data takes place simultaneously. Acyclically retrievable diagnostic data such as minimum or maximum values, or errors such as wire breaks or short circuits allow for condition-based maintenance, ensuring higher plant uptime. The diagnostic data can be accessed even during operation.

The flow rate in a cooling circuit is precisely monitored using magnetic-inductive inline volumetric flow sensors of the SM series. If an error occurs, the diagnostic data is transferred from the master to the controller. The failed sensor is identified unambiguously.

Detection of media, foam and soiling

Use IO-Link and see what the sensor is measuring. Many smart sensors can be used as binary sensors only, e.g. to provide a switching signal when an upper or lower level is reached. Via the integrated IO-Link interface the sensors also transmit the current process value. This allows for example differentiation between the product and the cleaning agent in the controller. It is also possible to detect foam or residual soiling after cleaning processes in order to protect the plant and the product.