Data centre environmental monitoring

Leveraging automation to optimise performance

Data centre environmental monitoring involves the continuous tracking and management of critical environmental conditions through a data centre facility. This includes monitoring factors such as temperature, humidity, airflow and water leaks, both in the cooling system and the ambient environment. Artificial Intelligence (AI) is driving an unprecedented increase in computational analysis, thus driving a subsequent rise in energy demand.

Effective environmental monitoring is important for data centres in order to ensure optimal performance, reliability and efficiency of the IT equipment and infrastructure.

Increase speed to market

Flexible, modular cooling equipment helps accelerate the deployment of data centres to meet increasing demand.

Improved efficiency

Continuous, real-time monitoring of cooling systems maintains optimal performance and eliminates risks of thermal throttling.

Achieve sustainability goals

Real-time monitoring of cooling systems provides the data necessary to benchmark and reduce excessive energy and water consumption.

IO-Link

provides a flexible communication protocol for connecting smart sensors. The purely digital signal provides a more accurate resolution compared to traditional analogue technology.

Level sensors

provide high degrees of accuracy and reliability for optimal machine design and are rigorously tested to prevent moisture ingress or other common causes of sensor failures.

Temperature sensors

provide real-time monitoring of the media and are rigorously tested to prevent moisture ingress or other common causes of sensor failures.

Flow sensors

are critical for monitoring flow rate, totalising functionality and media temperature in real time via IO-Link communication.

Oil humidity sensors

continuously monitor oil quality by measuring the relative humidity and temperature of coolants. Plan maintenance before harm or corrosion to equipment by means of early detection of water in oil.

Display controllers

simplify machine controls. They combine a HMI display, machine control and data connection for remote monitoring.

Vibration sensors

offer a plug-and-work option with IO-Link technology to monitor the four main causes of fatigue, and send that data to any higher-level software system.

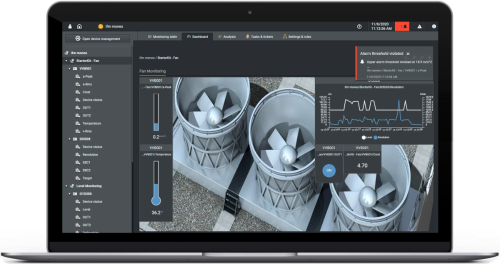

moneo software

seamlessly visualises machine data and provides alarm notifications through an intuitive software user interface.