The Y path

Why Y path?

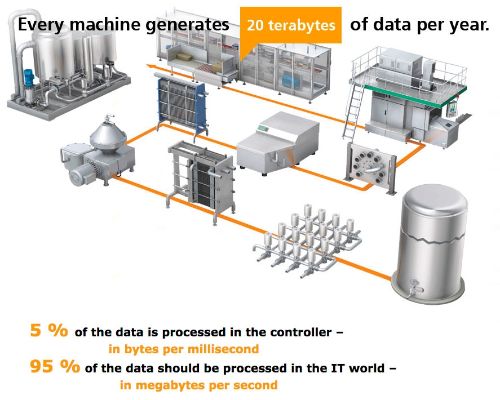

The Y path directly provides this 95 % of the process data without detour via the controller. IT and automation technology are integrated in a simple and economical manner for the first time - from the sensor to SAP®.

Use the advantages of the Y path for intelligent solutions from the fields:

- Condition Monitoring,

- Energy Monitoring,

- Quality Monitoring,

- Track & Trace

- Remote Services

Interface for factory networking.

The hardware and software components allow direct networking of all connected sensors and actuators with a local server via an Ethernet network. Using this connection, machine data, process parameters and diagnostic data can be directly read and processed by the IT.

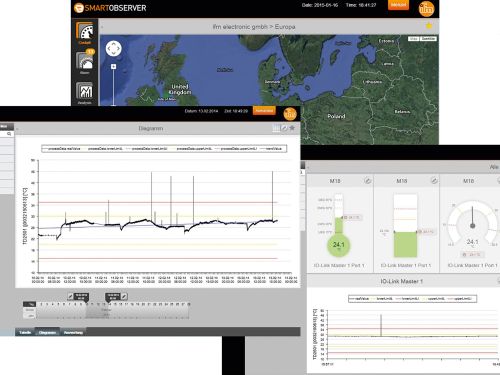

The easy-to-use server software LINERECORDER SMART OBSERVER enables data evaluation by means of customer-specific cockpits. Using the same communication mechanisms, it is possible to directly couple machines and exchange production-related data.

If and which sensor data the PLC transmits to the process control level needs to be defined in the PLC program. Reportings and analyses can also be transferred to higher levels. The prerequisite for this is an additional adaptation of the PLC program.

From sensor to SAP.

For the first time, sensor data can be directly transmitted to the business software - and this on a factory-wide or even worldwide level. Evaluation of the obtained data in real time enables an increase in production efficiency and energy savings in the context of Industry 4.0.

The Y path to the Smart Factory.

Complete networking and extensive use of machine and sensor data are the declared goal of Industry 4.0. Sounds easy - but still fails in practice because of obstacles.