Optimizing Procurement & Material Planning: How Molex Connected Kinaxis to SAP with ifm

Molex©

To improve supply chain visibility and decision-making, Molex implemented Kinaxis Rapid Response to extend its supply chain planning capabilities beyond SAP ECC. However, integrating advanced planning insights from Kinaxis with SAP’s MRP exception messages proved to be a challenge. To resolve this, Molex partnered with ifm, ensuring a seamless connection between Kinaxis and SAP for more efficient procurement, material planning and exception handling.

The challenge: Bridging the visibility gap

Molex manages its materials planning outside SAP using Kinaxis Maestro (previously Rapid Response), which enhances their ability to predict demand and adjust production schedules dynamically. However, this shift came with a significant drawback:

Loss of SAP MRP exception visibility

Group 7 messages which govern scheduling adjustments (e.g., schedule in, schedule out, cancellations, and plan adherence) were no longer accessible within SAP.

Lack of actionable insights in SAP

Purchasing teams could not efficiently process Kinaxis exceptions, leading to delays in responding to critical supply chain adjustments.

Fragmented workflows

Users had to switch between multiple platforms, increasing the risk of misalignment and inefficiencies.

Adding to the complexity, 30,000 exception messages were being generated daily, making it difficult for planners to separate urgent issues from routine alerts. As a result, purchasing teams spent excessive time sifting through unnecessary messages rather than focusing on resolving high-priority MRP exceptions.

Key requirements

Molex needed a fully integrated solution that would:

- Display group 7 exception messages within SAP

- Enable corrective actions directly within SAP, such as:

- Converting Purchase Requisitions (PRs) to Purchase Orders (POs)

- Mass rescheduling PRs and POs with a single click

- Providing an overview of production and purchase orders linked to exception messages

- Displaying Kinaxis exceptions inside SAP

The solution: Connecting Kinaxis to SAP with ifm

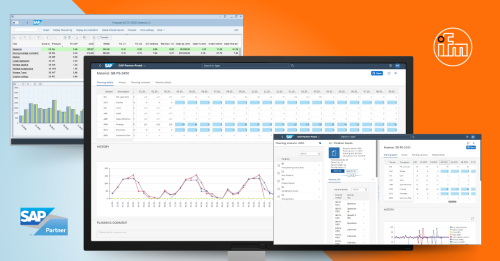

Molex implemented ifm’s Procurement & Material Planning solution, which offered a seamless bridge between SAP and Kinaxis. This integration allowed Molex to import, visualize, and act upon Kinaxis messages within SAP without switching systems.

How it works

Automated data flow

Kinaxis exception messages are stored in a custom ifm-developed table, which is updated in SAP daily.

Embedded exception visibility

Exception messages from Kinaxis are seamlessly displayed within SAP, integrated directly into ifm’s main execution area. This ensures a unified view of Kinaxis and SAP data, including MRP Main List, Purchase Orders, Production Orders, and Purchase Requisitions, allowing planners to manage and act on exceptions without switching systems.

Enhanced processing features

- A mass schedule button allows purchasing teams to reschedule multiple POs based on recommended Kinaxis dates.

- Exception source identification ensures that Kinaxis exceptions are cleared marked as “RR” (Rapid Response) messages within SAP.

- Processing indicators help track which exceptions have been addressed, improving visibility and efficiency.

Measurable impact

Before partnering with ifm, 30,000 exception messages flooded Molex’s planners daily, making it difficult to distinguish urgent issues from routine alerts. With advanced filtering, that number was reduced to just 8,000 actionable messages—a 75% reduction in noise, allowing teams to respond faster and more effectively to real supply chain disruptions.

By integrating exception message filtering and automation, Molex transitioned from a decentralized planning model to a more collaborative and centralized structure. This restructured approach enhanced real-time decision-making, cross-team coordination, and overall MRP efficiency by 40-50%. With fewer manual interventions and a more streamlined workflow, planners could focus on high-value material planning strategies instead of time-consuming administrative tasks.

Key business outcomes: Increased efficiency and seamless workflows

- Enhanced visibility: Kinaxis exceptions are now directly accessible inside SAP, ensuring full transparency.

- Improved decision-making: Purchasing & Material Planning teams can take immediate corrective actions on exception messages.

- Operational efficiency gains: The mass rescheduling function significantly reduces manual processing time.

- Seamless user experience: Employees can work entirely within SAP, reducing the need for cross-platform navigation.

Conclusion

Molex’s collaboration with ifm Supply Chain successfully bridged the gap between Kinaxis Rapid Response and SAP’s exception management, eliminating silos and enhancing end-to-end procurement visibility. Through native SAP integration, Molex optimized its purchasing & material planning workflows, enabling teams to respond to supply chain exceptions in real time—all within a single, unified system.

By automating exception filtering and centralizing procurement & MRP operations, Molex reduced non-value-added exception messages by 75% and achieved a 40-50% increase in efficiency. This shift allowed procurement teams to focus on strategic supply chain initiatives rather than manual exception management, driving greater operational agility.

With ifm, Molex now operates with a fully connected, efficient, and proactive supply chain management system, ensuring faster decision-making, increased productivity, and streamlined procurement execution.

Want to achieve similar supply chain success?

Contact ifm Supply Chain today to learn how our native SAP optimization solutions can optimize your procurement and planning processes.