- Supply Chain Management

- Integrated Supply Chain Execution

- Procurement & Material Planning

Supply Chain Excellence (SCX) for Procurement

Smarter execution inside SAP

Automate procurement and MRP. Optimize inventory. Eliminate execution gaps.

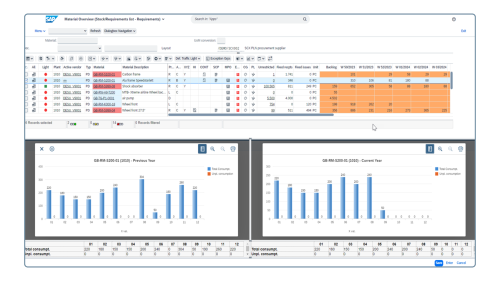

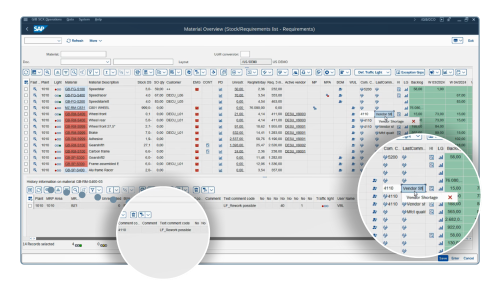

Supply Chain Excellence (SCX) for Procurement is more than an MRP tool—it's your execution cockpit for procurement, inventory, and planning inside SAP. Fully embedded in ECC and S/4HANA, SCX unifies over 50 SAP transactions into a single interface for faster decisions and fewer manual steps.

Full embedded in SAP. No middleware. No delays.

Works natively in SAP ECC & S/4HANA

Automates 50+ procurement and MRP transactions

Centralized view of requisitions, orders, vendors, and exceptions

Go-live within 8 - 12 weeks

Key features

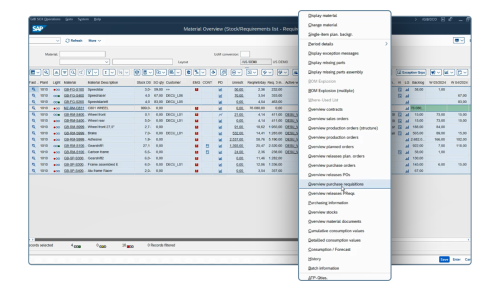

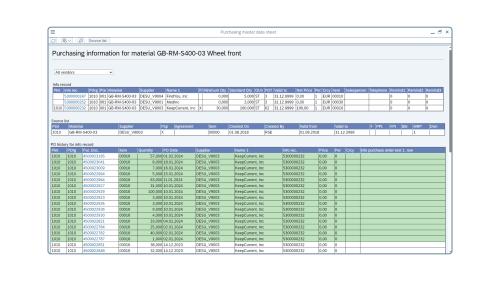

Purchase order management

Create, manage, and track purchase orders with full visibility into order status, quantities, pricing, and delivery timelines. The system also enforces minimum order values and quantities to avoid unnecessary costs.

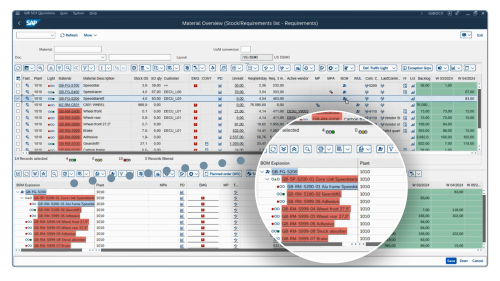

Multi-level Bill of Materials (BOM) management

Analyze BOM structures across multiple production levels and plants. Quickly visualize component dependencies and identify impacts from shortages or design changes.

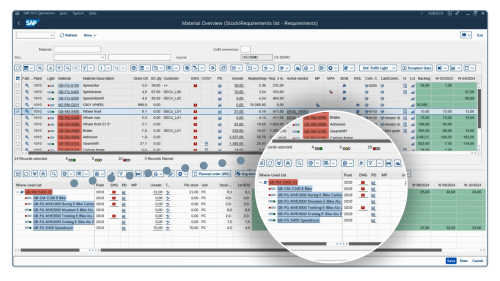

Where-used list anaysis

The where-used list shows every parent assembly that relies on a given part. Similar to BOM explosion, the where-used list can also be analyzed across different plants.

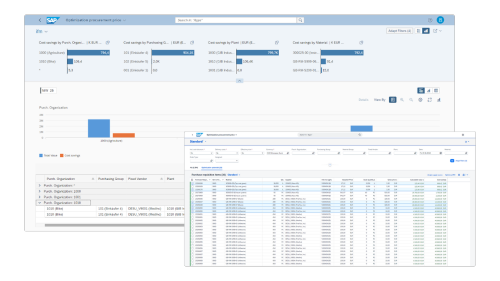

Vendor management and source selection

View vendor performance, historical pricing, and lead times in one place. The cockpit highlights the best source of supply by evaluating cost, delivery time, and vendor reliability—enabling smarter, faster procurement decisions.

Optimize by cost, cycle time, and vendor constraints

Automatically factor in key variables like freight costs, minimum order quantities, price breaks, and delivery delays. Ensure every purchase is optimized for cost-efficiency and execution speed.

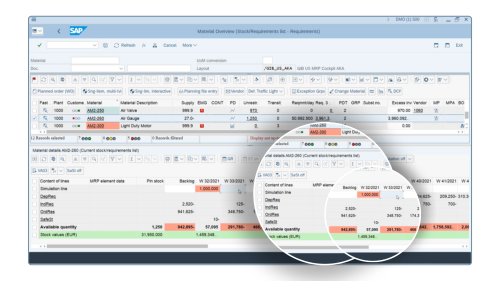

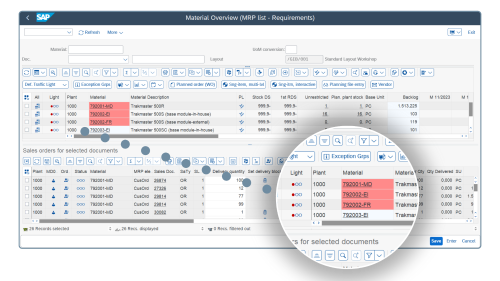

Advanced planning & simulation

Model supply chain changes before executing. Run what-if scenarios for new orders, transfers, or production shifts—with a visual layout that extends beyond standard MD04.

Exception-based execution & alerts

Prioritize critical issues using intelligent filters and customer-specific exception messages. The cockpit highlights urgent actions to prevent disruptions and reduce manual review time.

Change history tracking

Track every change to purchase orders, material documents, and planning actions. Provides complete transparency for compliance, reporting, and team accountability.

Supply Chain Excellence: A Buyer’s perspective on optimized supply chain execution

Watch the demo now & see how SCX transforms operations

Struggling with supply chain inefficiencies? SCX enhances visibility, automation, and efficiency across your procurement, inventory, and fulfillment processes—all seamlessly integrated within SAP ERP.

Use cases

MRP execution with supplier constraints

Adjust sourcing decisions based on vendor lead time, MOQs, or risk scores.

Inventory reduction without risk

Use safety stock optimization and coverage views to reduce excess inventory.

Real-time response to shortages

Use exception alerts to resolve missing parts or delayed deliveries fast.

Multi-plant coordination

Plan and execute procurement across distributed sites from one cockpit.

Ready to streamline procurement in SAP?

Let your buyers and planners focus on execution—not transactions. With SCX for Procurement + the Execution Cockpit, you can automate requisitions, act on exceptions, and optimize vendor decisions—all within SAP. Fill out the form below to book a personalized demo and see how SCX simplifies procurement and material planning inside SAP.