- moneo IIoT platform

- Products

- moneo Industrial AI Assistant

- SmartLimitWatcher

moneo SmartLimitWatcher

Moneo SmartLimitWatcher is an AI-based software product. It is used to dynamically monitor threshold values in complex machine and production processes in companies. The intelligent software alerts you to anomalies in key process values such as temperature, pressure or vibration.

|

Improve Prevent unplanned downtime by predicting failures and increasing machine availability. |

Maintain Improve your process performance by monitoring and detecting deviations in real time. |

Optimise Reduce operating costs by monitoring energy consumption at machine level. |

Benefits of SmartLimitWatcher

Simple

No data science expertise required. Pragmatic solution with simple 5-step wizard for those responsible for production and maintenance.

Convenient

Automated data preparation, model training and quality control. No complex data preprocessing required.

Smart

Automated selection of the best-fit AI model, including verification of monitoring accuracy.

Reliable

Time-based and condition-based monitoring. Continuous background monitoring using dynamic expectation ranges for the target variable.

Customisable

Adjustable anomaly detection sensitivity. Customisable warnings and alarms.

5 steps to intelligent process monitoring:

the 5-step wizard

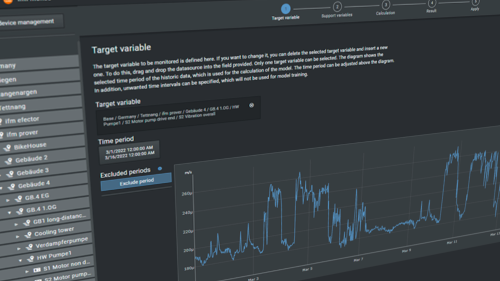

moneo SmartLimitWatcher offers a set-up wizard that makes the software easy to use. In just five steps, the intelligent monitoring tool can be activated without expert support.

moneo SmartLimitWatcher monitors multi-stage, complex industrial processes and machines. The software automatically detects anomalies based on sensor data such as temperature, flow and vibration and sends warnings and alarms based on dynamic thresholds.

Customers who prefer to monitor individual measured values can use moneo PatternMonitor. This AI tool identifies structural changes in critical process values. Automatically generated alarms enable appropriate measures to be initiated at an early stage.

By the way:

further intelligent tools in the area of predictive maintenance are already in development and will soon be added to the existing Industrial AI Assistant solutions.