- Supply Chain Management

- SAP-based software

- New Release 25.0

- Manufacturing

Highlight features from manufacturing

Take your production planning to a new level

Release 25.0 contains many new features and improvements for production planning and control. Newly developed and enhanced Fiori apps provide support for detailed graphical planning and the confirmation of production orders. In addition, there is now the option of graphically displaying the use of production resources/tools. Our AI-based Software Factory Optimization Excellence has also been expanded. With the new Fiori overview page, you will be able to better assess the optimisation results in the future.

And that's not all: look forward to these and even more innovations!

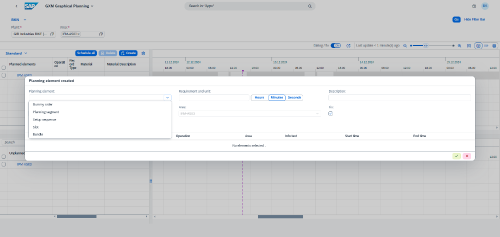

Enhancements of the Fiori app “graphical planning board”

Additional functions have been added to the graphical planning board. This means that even more planning functions can be carried out directly in the app in the future.

New additions include information on:

- missing parts

- production resources/tools (PRT)

- components

Creating and changing planning objects

The function “creating and changing planning objects” allows you to create and edit the objects dummy order, planning sequence, slot, block and bundle directly in the graphical planning board, which significantly simplifies the planning process. The objects behave analogously to our Supply Chain Excellence (SCX) for Manufacturing software.

New Fiori app: “confirmation time event” in the clean core

The Fiori app “confirmation production order, time event (v2)” is a new development of the existing app “confirmation production order, time event”, considering the SAP clean core specifications. The range of functions is largely identical.

The app makes it quick and easy to enter feedback on the production order operation. The system guides users step by step and ensures that all feedback is entered correctly and in the right order (e.g. start setup – end setup).

The result: improved data quality and fewer errors in the production process!

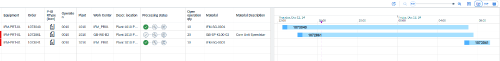

Visualisation of the use of production resources/tools

In the existing tabular display, it is sometimes difficult to recognise overlaps when using production resources/tools (PRT) in detailed production planning.

To avoid overlapping conflicts, a new feature for the graphical visualisation of the temporal PRT utilisation was developed with Release 25.0. The new function can be accessed both from the planning of the SCX for Manufacturing solution and from the ifm PRT administration.

Benefits:

more transparency

fewer planning errors

faster planning processes due to minimised delays

more efficient detailed production planning

Dashboard container in the planning

In the planning transaction, the capacity utilisation data from the SCX for Manufacturing dashboard can be displayed in a separate container. The dashboard areas to be displayed can be defined in advance in the planning set. When opening the planning board, this information is adopted immediately.

The planning work centres and the work centres displayed in the dashboard can differ. This enables a clear visualisation of the effects on other work centres directly during detailed planning!

In addition, the dashboard is automatically updated with each scheduling, so that the data is always up-to-date.

A clear advantage for precise and efficient planning!

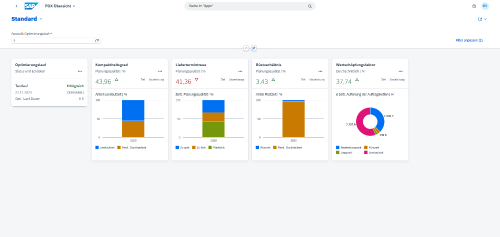

Factory Optimization Excellence (FOX)

Fiori overview page for a visual display of the optimisation results

With ifm's Factory Optimization Excellence (FOX) software, an optimised production plan can be created using AI algorithms. However, the solution of the AI-based optimiser is difficult for humans to understand.

To help you assess the quality of the results, Release 25.0 offers a new Fiori overview page that graphically displays the relevant key figures of the optimisation run.