Holistic optimisation of your supply chain processes with Supply Chain Excellence

SAP-based software for your intralogistics

- Focus on the customer: improve your service level and realise preferred delivery times

- Keep an eye on costs: discover hidden treasures in your inventory and materials management

- Increase user efficiency: all urgent to-dos in the work queue every morning, no annoying transaction hopping

- Conserve resources: steer instead of swim with automatic matching of capacities and demands

- Expand transparency: all relevant information at the push of a button, in real time, in one database, served user-related

How can you manage your digitalised supply chain on a strategic and operational level?

The move to SAP S/4HANA is compulsory, but not a foregone conclusion. The decision, greenfield or brownfield approach, is a fundamental strategic question with enormous financial, structural and personnel implications.

It is also linked to the vexed question of whether the right decision has been made and when the first successes will become apparent. Should there really be no low hanging fruits? Are quick wins out of the question? At ifm, we have been dealing with this question for a long time and can answer it today: Absolutely!

The greatest benefit is transparency. We simply make the operative processes much more transparent and, therefore, know what the result is behind the core processes. This makes much more sense than simply running a process without knowing what the result is or should be.

The move to SAP S/4HANA

Quickly improve SAP-based supply chain management

This is how it works: The Supply Chain Excellence (SCX) software solution from our company is seamlessly integrated in SAP such that users at all times move within their familiar SAP design without noticing that they are switching back and forth between applications.

The central advantages of the ifm solution for supply chain management are immediately available and visible:

- Simulation of scenarios and much more

- Delivery backlogs, base sets and missing parts at a glance

- User-related display of critical materials including early warning system

- Graphical representation of all relevant surplus and shortage situations

- Daily workload and need for action visible in personal working memory

Data consistency via direct access to the SAP core

And the data? Data consistency by way of direct access to SAP Core. Therefore, you ALWAYS work with the correct, up-to-date database and this applies to every process step, every department, at any (real) time.

Long-standing GIB customers know about the advantages and have long been convinced that a change to SAP S/4HANA absolutely has to be made with the GIB intralogistics solution.

Is there also something new? An incentive that brings rapid benefits in the SAP S/4HANA system? That too! Heres how 5 striking logistics metrics show the quality of your supply chain in the areas of demand planning, inventory management, procurement, manufacturing and sales & distribution.

These Indicators are based on a sophisticated system of key figures, which is fed exclusively from the SAP Data Core. For example, the overall equipment efficiency OEE, production backlogs or material availability are used to evaluate the supply chain process quality.

All the necessary figures, data and facts for evaluating the process sections can be found in your SAP Core. These process indicators are condensed into an SCX Indicator, which, like all other parameters, reflects the quality of your supply chain in percent. Now not only the internal areas can measure themselves against each other, the logic also works across plants or companies.

Whether in series production, process manufacturing, automotive, special machine construction or trade the underlying KPIs are always the same. Therefore, sales planners, production planners or inventory and requirements planners quickly get talking about a small index.

It does exist the quick and yet sustainable benefit in the SAP S/4HANA conversion.

Supply Chain Excellence is an enabler for your changeover to SAP S/4HANA.

What challenges are you facing?

- Competition within your own company?

- Competing with other supply chain experts?

- Starting the changeover to SAP S/4HANA with quick wins?

Björn Dunkel, Managing Director of SAP Silver Partner GIB, explains in an interview why the approach of the new Supply Chain Excellence solution is so revolutionary and why competition between experts internally and externally is an incentive to be better and more successful.

How good are YOUR supply chain processes?

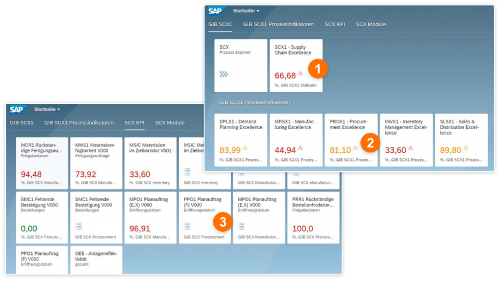

The SCX indicator shows at a glance whether your supply chain functions across all process stages of your intralogistics.

The second level illuminates the sub-steps and simply and clearly shows in which planning phase optimisation potential is hidden.

In the third level, sophisticated key figures allow conclusions to be drawn about the specific problem, for example

- High capital commitment due to excessively large safety stocks,

- Excessive warehousing due to poor batch sizes in production or

- faulty material requirements planning due to imprecise sales planning.

You, therefore, make individual works in the company comparable or measure yourself against other companies. Perhaps you will also ask at the next SCM meeting: What does your SCX indicator look like?

- The SCX1 indicator reflects the quality of the entire supply chain process in a single figure. The Delta shows whether an improvement or deterioration has occurred.

- The second view breaks down the process section that has had a positive or negative influence and whether the process performance has moved upwards or downwards.

- The key performance indices provide information about which parameters are used for evaluation, e.g. production backlogs, material availability or overall equipment effectiveness (OEE).

Stop silo thinking

More transparency and communication in your supply chain

The core of supply chain excellence is the control loop, which consists of the process steps analysing, planning, executing and optimising and continuously ensures continuous improvement and links all process steps of the supply chain with each other.

The APEO principle

Price volatility, shortages, new technologies, changes in the environment of market competitors, adjustments in working conditions, new laws and regulations the framework conditions in supply chain management are constantly changing. Only those who are willing and able to react quickly and make the right decisions will prevail in the market.

Reliable tools and processes are required to successfully master this intelligent and perpetual change process. The APEO principle offers a clear structure and is embedded in a highly efficient software system that reliably navigates you through the complex supply chain processes.

The user maintains an overview of his area of responsibility at all times, always knows what needs to be done, always accesses the most up-to-date data from SAP Core and is, therefore, perfectly positioned to optimise the logistical processes in and with SAP and, therefore, make the company successful.

- Comprehensive control and analysis options

- Simulation of scenarios and working with versions

- Connection to the production level (vertical integration)

- Holistic and process-based view of the supply chain

- Meaningful formulae and comprehensive system of key figures

- Usability and simplicity by way of intelligent user interfaces in Fiori design

Certified by SAP

Request a demonstration

Would you like to learn more about our supply chain optimisation solutions in SAP? Are you looking for a solution that allows you to automatically transfer data from machines or sensors to SAP and start intelligent processes? Complete the form and request your demonstration on-site or online now.