Highlight features from procurement

New convenience for purchasing and scheduling

There are new features in procurement: Timely rescheduling in case of supplier failure, setting up user-specific action requirements with dynamic jumps, increasing availabilities and minimizing freight costs with the line buy function, controlling and managing the supply situation using planned independent requirements, clear stock transfer with the new detailed window for reservations and saving planning file entries in PP/DS.

Simply scroll and browse!

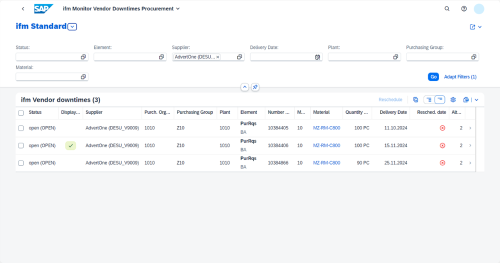

Timely planning in case of vendor downtimes

Plant vacations, machine breakdowns, logistics problems – there are many reasons why vendors are unable to deliver for long periods of time. To ensure that production can continue seamlessly, action must be taken, e. g. alternative vendor selection or rescheduling.

There is no support for this in the SAP standard, which is why we at ifm have addressed the problem and offer a solid solution with the new release. Instead of creating emergency plans outside the SAP system, purchasers and MRP controllers can store planned and short-term downtimes in the system. Recommendations for action and alternatives for vendors are then automatically displayed in the worklist and the user can go directly to the selected transaction with a single click.

Clear, simple and fast!

Vendor downtimes – forward-looking procurement

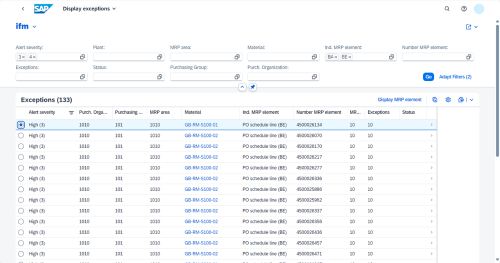

Set up user-specific need for action

“There is a need to act now!” Clearly recognizable and unambiguously addressed, the user sees the need for action in his worklist. The previously defined, organization-specific assumptions and statuses of the MRP elements are clearly displayed and can be processed directly from the application.

This leads to even greater efficiency and speed!

App: Need for action

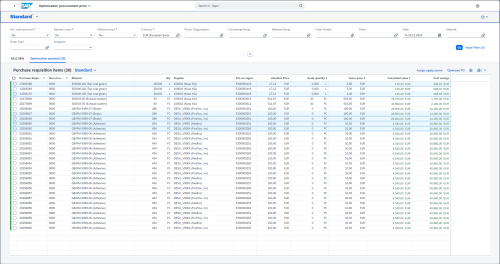

More availability, lower freight costs through line buy

More availability and lower freight costs with the line buy of the ifm procurement solution. Delivery rhythms and target stock levels are used to optimise orders, supplement demand indicators and plan materials according to range.

This is possible for both individual suppliers and supplier groups.

Simply become more efficient!

Line Buy – order optimisation with ifm restrictions

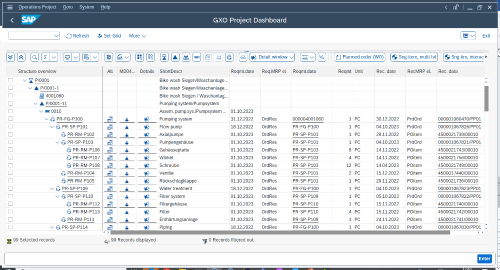

Operations project – analysing planned independent requirements

What does the supply situation for planned independent requirements look like? With the new release, you can obtain this information at the click of a mouse and it is always up-to-date.

Previously it was already possible to drill down into the complete production structure and reservations for all projects and sales orders, but now this also applies to planned independent requirements.

Make targeted selections according to planning periods, requirement plans and other criteria.

This way, you can keep an eye on supply problems and delayed receipts!

Evaluate planned independent requirements in the Operations project

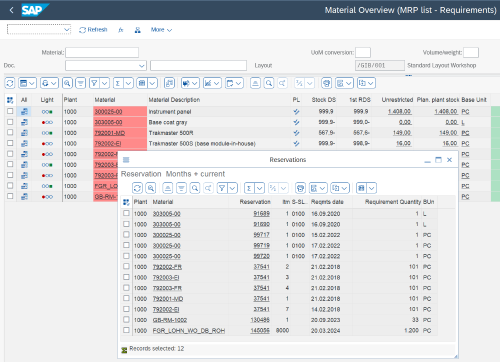

New detail window for a better overview of reservations

Until now, stock transfer reservations were very inconvenient to handle, namely in the MD04 window. The new release now offers a separate selection tab and a separate detail window. This allows you to schedule and make reservations in a targeted and clear manner.

Jumps to MD04 and MB23 are also available in the new window.

Finally, you can reserve, schedule and reschedule without a magnifying glass!

Detail window for reservations

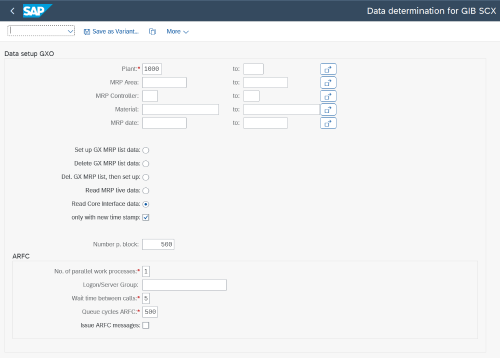

Saving planning file entries in embedded PP/DS

Data structure based on the CIF interface (beta function)

So far, the data setup for Operations and Operations Project supports classic MRP and MRP Live. If Operations is used in conjunction with embedded PP/DS, the information regarding the timing of material planning is lost. The new release closes this information gap: in Release 25.0, all time entries for all material planning are stored in a newly developed planning file as soon as data or orders are written via the CIF interface.

On the basis of these planning file entries, a data setup for the CIF interface can then be carried out via the usual data setup programme (transaction /GIB/DCO_DATA). This enables the use of the Alert Monitor, access to Operations in MRP list mode and mapping between requirements and cover for the Operations Project.

Data structure based on the CIF interface