Automotive automation: Real-time improvements in manufacturing

As vehicles change from gas power to hybrid and electric, automotive manufacturers need to stay agile to control costs and expand options for consumers. By increasing access to machine data, manufacturers can gain more insight into their assembly processes. Smart manufacturing includes:

-

Enhanced data: Collect more process data with connected sensors.

-

Real-time alerts: Implement Edge Computing to protect equipment.

-

Predictive analytics: Build verified digital twins with Artificial Intelligence (AI).

Unlock the power of production data to make more informed decisions and benefit from improved quality, reduced costs, and more sustainable manufacturing.

Monitor critical assets continuously

Throughout the automotive production process, manufacturers can benefit from increased information about the performance of critical machines using an asset health management solution. Improve efficiency with continuous monitoring of machines to confirm systems are performing as expected, to receive warnings when small changes threaten production, and to receive advance notice if a shutdown is imminent.

Benefits of automotive automation

Improve asset health

Real-time condition monitoring and analysis of critical machines improve decision-making. Optimize maintenance plans and forecasts for more efficient production schedules.

Improve product quality

Simplified inspection solutions and increased traceability throughout production improve final product quality.

Achieve sustainability targets

Improved machine condition monitoring and predictive alerts reduce water consumption, improve energy optimization, and streamline regulatory compliance.

Access real-time machine data

To gain real-time insight into machine health, manufacturers access digital sensor data via IO-Link technology. The process values are sent to the PLC for automated machine control and separately to higher-level software for further analysis. This communication "Y-path" allows manufacturers to unlock their production data for trending and analysis without burdening the PLC. Optimize and maintain critical equipment with real-time monitoring of:

Accessing machine data enables manufacturers to forecast machine repairs and optimize maintenance plans before a catastrophic failure occurs during production. Real-time data enhances production processes, safety, and quality control.

Improve processes with actionable insights

Automotive manufacturers receive immediate insight into machine conditions to make more informed decisions with enhanced vibration and oil quality monitoring. Statistical modeling and Artificial Intelligence (AI) enable predictive alerting to improve machine performance.

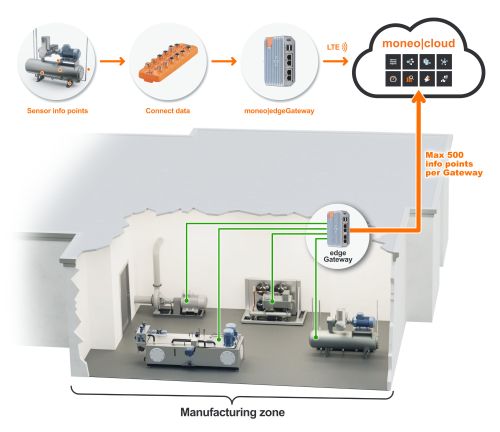

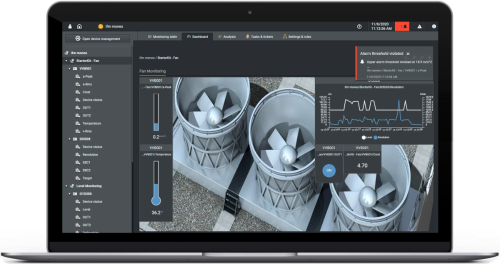

With moneo Cloud software, manufacturers can create drag-and-drop dashboards in just a few hours to start monitoring real-time machine health. The intuitive interface makes it simple to get started without advanced computer programming knowledge. Designed by manufacturers for manufacturers, moneo simplifies proof-of-value projects and scales easily.

Simplify machine monitoring

As customers want more choices, manufacturers must rethink production lines to maintain throughput levels. Lean manufacturing cells are more flexible for quick changes but require an agile technology stack. Choosing smarter sensors with simplified setup, parameterization, and multiple communication protocols ensures maximum flexibility. Achieve this with a more modular system architecture:

Simplify reprogramming with interoperable technologies to stay lean and accommodate quick changeovers. Gain additional insights by simplifying machine data collection, real-time analytics, and long-term trending.

Reduce downtime with real-time data

Reducing planned and unplanned downtime is a significant benefit of real-time asset health monitoring. With more information about machine condition, automotive manufacturers can:

- Plan better maintenance schedules

- Bring certainty to production schedules

- Optimize supply chain resiliency

Accelerate planned stops, including line changeovers and planned maintenance. With intuitive and simplified sensors, it is easier than ever to change parameters to accommodate new vehicle types, colors, or sizes. With real-time monitoring, maintenance is optimized to avoid machine failures and inefficient time-based schedules. Find out how an automotive supplier saved an estimated $500,000 in downtime costs by implementing stamping press condition monitoring.

Reduce scrap rates

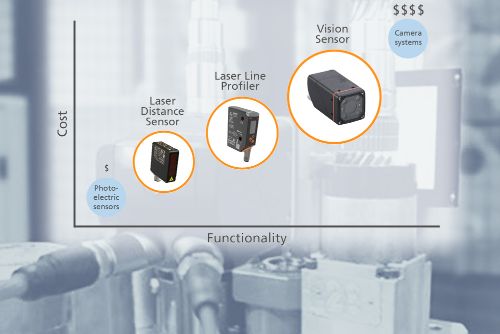

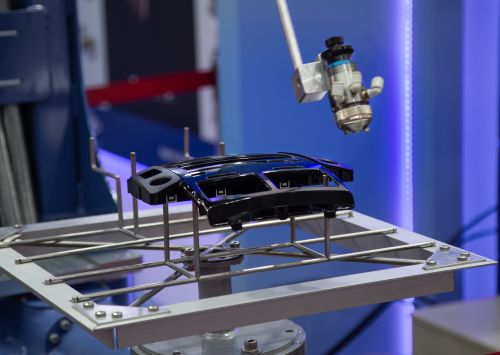

With innovative vision technologies, automotive manufacturers can implement automated systems that:

- Confirm parts are seated correctly

- Dispense the correct amount of adhesive or paint

- Optimize flow rate, temperature, and pressure

Real-time monitoring proactively alerts manufacturers to slight deviations in process values that impact product quality. This gives manufacturers time to address an issue before it escalates into a catastrophic failure.

Improve traceability throughout production

Improve product quality, supply chain planning, and shipment accuracy with better track and trace solutions. RFID technologies today offer simplified solutions for tracking:

Automotive manufacturing requires hundreds of components and assembly steps. With smart sensors that are simple to deploy, manufacturers can track vehicles throughout production from raw materials to finished goods.

Improve abatement systems

Paint booths are often a bottleneck process for automotive production. Fans are critical for ventilating Volatile Organic Compounds (VOCs) during the painting process. They ensure the correct capture and disposal of these compounds to meet strict air quality regulations. A failure during production can stop the entire manufacturing line. Real-time vibration monitoring of fans ensures abatement systems are always available during production. Automated systems collect machine health data automatically to streamline recordkeeping requirements.

Improve energy efficiency

Relying on aggregate energy consumption data at a plant level makes it difficult to determine inefficient equipment. Real-time energy consumption data enables operators to intervene quickly before wasting expensive resources. With asset-level monitoring, manufacturers identify energy consumption by machine and analyze which equipment is more efficient or in need of maintenance.

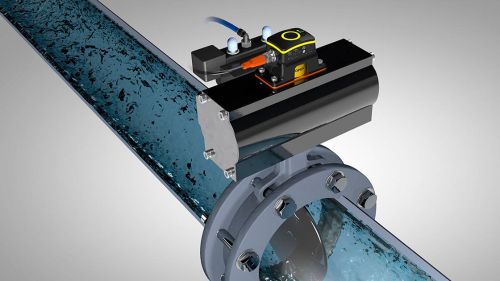

Reduce water consumption

Inefficient water consumption leads to wasted resources and costs. Quantifying water consumption is the first step toward identifying improvements and implementing water management strategies. Real-time water usage monitoring enables manufacturers to identify and reduce inefficiency in their systems. Collect real-time data with:

Manufacturers can leverage this data to implement water-saving strategies, such as identifying leaks or inefficiencies and adjusting machine settings.

IO-Link technology is the foundation of smart manufacturing. It is a flexible communication protocol that allows you to send multiple process values over one wire, increasing access to your production data.

IO-Link vibration sensors offer a plug-and-work option for real-time vibration monitoring. Monitor the four main causes of fatigue, and send that data to any higher-level software system for further analysis.

Oil humidity sensors continuously monitor oil quality by measuring the relative humidity and temperature of coolants. Plan maintenance before harm or corrosion to equipment with early detection of water in oil.

moneo|software seamlessly visualizes machine health, trends process data, and implements alarms. It is built for easy integration and setup. Get started in hours, not weeks.

Smart flow sensors are critical for monitoring flow rate, totalizing functionality, and media temperature in real time via IO-Link communication. Increase the accuracy and reliability of process data with a fully digital signal.

Pressure sensors or level sensors provide high degrees of accuracy and reliability for optimal machine design. Designed to withstand harsh production environments, they are rigorously tested to prevent against common causes of sensor failures.

Temperature sensors provide real-time monitoring of the media. They are rigorously tested to prevent moisture ingress or other common causes of sensor failures.

Laser distance sensors use Time of Flight (ToF) technology to ensure high performance when measuring metallic, rounded, or matte targets.

RFID over IO-Link solutions simplify the integration of RFID systems within an existing IO-Link network.

IO-Link Image-based code readers send Optical Character Recognition (OCR) inspection and barcode scan data via an IO-Link master directly to ignition or higher-level software systems.

Preparing for the future of the automotive industry

The automotive industry is transitioning to a new era. As manufacturers pivot to meet the demand for hybrid and electric vehicles, they need access to more production data to optimize operations and supply chain planning. Their technologies need to be flexible and interoperable to better prepare for the future. Find out how automotive manufacturers can better leverage ifm solutions to meet the demands of the future.