- moneo IIoT platform

- Improve manufacturing efficiency

Eliminate unplanned downtime due to equipment failures

Availability losses include unplanned stops, such as equipment failures, and planned stops such as machine setup and recipe changeover time. Use real-time maintenance (RTM) technologies in your production plants to increase machine availability, ensuring throughput and minimizing material losses.

moneo is an Industry 4.0 software platform. The integrated algorithms enable predictive maintenance for many critical industrial machines and convert your sensor data into valuable insights. Receive notifications prior to a machine failure, so you can plan preventive maintenance work in advance.

Increase asset health with

Predictability

Increase the availability of your production equipment.

Process stability

Your cycle times are never affected by damaged machines.

Self-monitoring

Your production systems automatically detect and report quality defects.

The evolution of maintenance technology

Real-time condition monitoring with

moneo Cloud

moneo provides recommendations for action

Unlock the hidden potential of your data with the moneo IIoT platform from ifm. With our moneo IIoT platform you can easily configure your sensors and masters and seamlessly collect your machine and sensor data. This data can be visualized, analyzed and monitored on dashboards. moneo informs you in case of process deviations and alerts you in good time. This allows you to improve machine availability, ensure your process quality and optimize energy consumption - regardless of whether you operate moneo in the cloud or on-premises. 95 % of our projects achieve an ROI within less than six months. Demo tour ➜

Real-time monitoring (RTM) dashboard in moneo

RTM protects against failures due to bearing damage.

Example of a basic set-up

| Components | Description | ||

|---|---|---|---|

|

Vibration is the most important measure of mechanical condition

|

|||

|

Temperature is another indicator of energy loss

|

|||

|

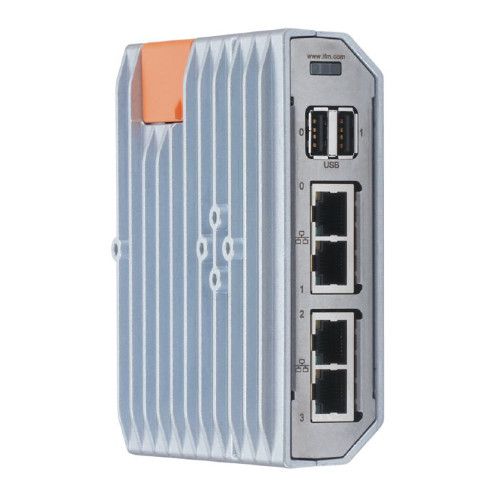

Data acquisition via IO-Link for standard PLC controller or data transfer to OT/IT systems

|

|||

|

Cloud connection for all IO-Link masters and vibration controllers

|

|||

Success stories

Find out how ifm has helped customers improve machine availability.