- moneo IIoT platform

- Improve manufacturing efficiency

- Optimize energy consumption

Optimize energy consumption through real-time monitoring

ifm develops customized energy monitoring solutions for you - tailored to your requirements. This will not only help you drive forward the digitalization of your company, but also discover new potential for saving energy and significantly reducing costs.

Measure energy consumption and waste at the machine level

Lower annual energy costs

By optimizing energy consumption and reducing waste, production facilities can save an estimated 25-50% per year, with 1/3 of this achievable without significant investment.

Tracking total costs

Identify process improvements with increased transparency by calculating the total energy cost per product produced or per business unit.

Tracking energy

consumption over time

Easily visualize energy waste from compressed air leaks by tracking energy consumption at machine or zone level over time.

Potential areas for energy savings

| Compressed air management | Pump/motor optimization | Heating system optimization | Cooling system optimization | |

|---|---|---|---|---|

| Savings* |

30 – 50% |

25 – 30% |

25 – 30% |

25 – 30% |

| How |

|

|

|

|

| Technology |

|

|

|

|

* Survey results from the German Energy Agency

Real-time compressed air monitoring with moneo Cloud

moneo generates recommendations for action

Steps to identify and reduce compressed air leaks

- Set a baseline for compressed air consumption

Install flow meters in a zone (branch to multiple machines) or at an end-use location (single machine) to establish the baseline for compressed air consumption. - Identify leaks

Measure compressed air consumption when equipment is shut down. If consumption is not at zero, there are leaks in the system. Check all connections and seals for leaks. - Document leaks and prioritize repairs

Repairing the biggest leaks results in the greatest savings. Repairing the most accessible leaks offers a quick start. Repairing the leaks that most impact machine performance improves the overall efficiency of the machine while reducing waste. - Adjust compressor control

Adjust the compressor control to meet reduced demand. Start/stop, load and relief, etc. will probably need to be adjusted. - Compare and publish results

Compare the results with the baseline and publish them. - Continuous optimization

A well-established leak detection program enables optimization of the existing system. This reduces the need for additional compressors.

Typical components for compressed air monitoring

| Component | Description | |

|---|---|---|

SD compressed air meter |

Traditional leak detection methods are all labor-intensive and unreliable

Air flow meters are the reliable alternative to traditional, labor-intensive leak detection methods. |

|

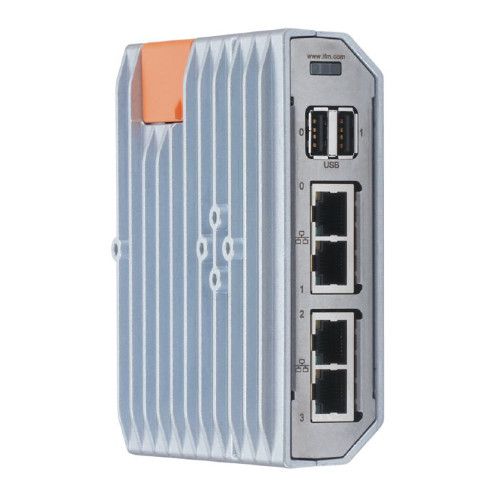

IO-Link master |

Data acquisition via IO-Link for standard PLC controller or data transfer to OT/IT systems

|

|

moneo edgeGateway |

Cloud connection for all IO-Link masters and sensors

|

Success stories

Find out how ifm has helped customers to optimize their energy consumption.